A wire display stores and displays several products, commonly used in retail settings. The base on which products are kept are made of latticed or interwoven metal strands. The term ‘wire display’ usually refers to small units or ledges which do not stand alone. Read More…

Acme Wire Products provides close tolerance wire fabrications using steel and stainless steel. Customized applications include a wide range of wire forms for many different applications. Acme works with wire from .050 to .500 diameter.

CUSTOM "Spring & Wire Form Specialists" - Ace Wire Spring & Form incorporates the latest CNC equipment technology to manufacture compression, extension, torsion springs, complex wire forms, and spring assemblies. We offer consistent quality, lower costs, on-time deliveries, and Design Engineering Assistance. Range from prototypes to long production runs - Family owned & operated since ...

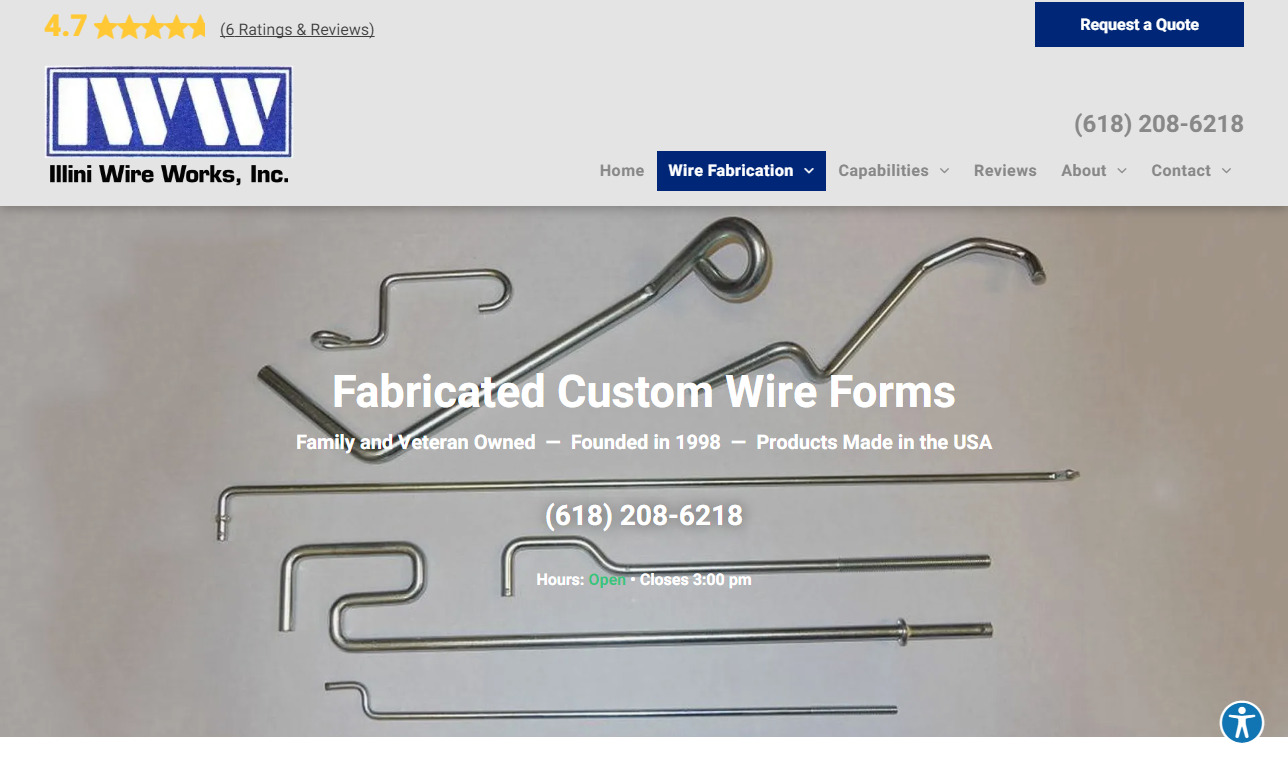

Illini Wire Works, Inc. stands as a distinguished leader in the realm of wire fabrication, providing unparalleled expertise in crafting custom wire forms and industrial fan guards. With a heritage of precision and innovation, we have become a trusted partner for clients seeking high-quality wire solutions tailored to their unique specifications. Illini Wire Works excels in the art of custom wire...

At Bloomingburg Spring & Wire Form, we manufacture custom compression, extension, torsion and double torsion springs, clock springs, wire forms, stampings and wire assemblies. Materials used include stainless steel, brass, bronze and other exotics by request. In addition to our engineering assistance and other services, we also make available a 24-hour RUSH emergency service. Whenever you need...

Stumped by a spring? Give it to our design team of professional spring engineers; they've got the experience it takes to get the job done right! In business since 1917, we manufacture compression springs, torsion springs & extension springs. We also carry stock springs. Murphy & Read Spring Manufacturing has design software on our site to design your own spring to be manufactured by us.

Here at Anderson Quality Spring Manufacturing, Inc., we take great pride in our position as a leading provider of wire forms, offering a comprehensive range of products, services, and capabilities to meet the diverse needs of our valued clientele. With our unwavering commitment to excellence and extensive expertise in wire forming technology, we stand ready to deliver innovative solutions that...

More Wire Display Manufacturers

Wire displays provide more vertical storage. often needed for displaying retail or commercial products, because they are made with multiple tiers or are stackable.

Considerations When Buying Wire Displays

Whatever the application is, it is always a great idea to find a proper wire display for one’s requirements.

The following considerations must be made:

Usage – What is the wire display going to be used for? Will it hold files, pastries or retail items?

Size – The wire display should fit the available space. Overall measurements such as length, width, and height must match the space available also.

Weight – The overall weight of products to be displayed should not exceed the display’s capacity. Exceeding a display’s weight capacity could possibly lead to dangerous and costly situations or mechanical failure.

Slit Size – Slits between wires are of concern too when buying wire displays. They should be smaller than all products the display stores to avoid the products from falling through.

Types of Wire Displays

Wire displays are mostly found in retail stores and used to display products where customers can easily see and pick items. Below are the common types or wire display normally found:

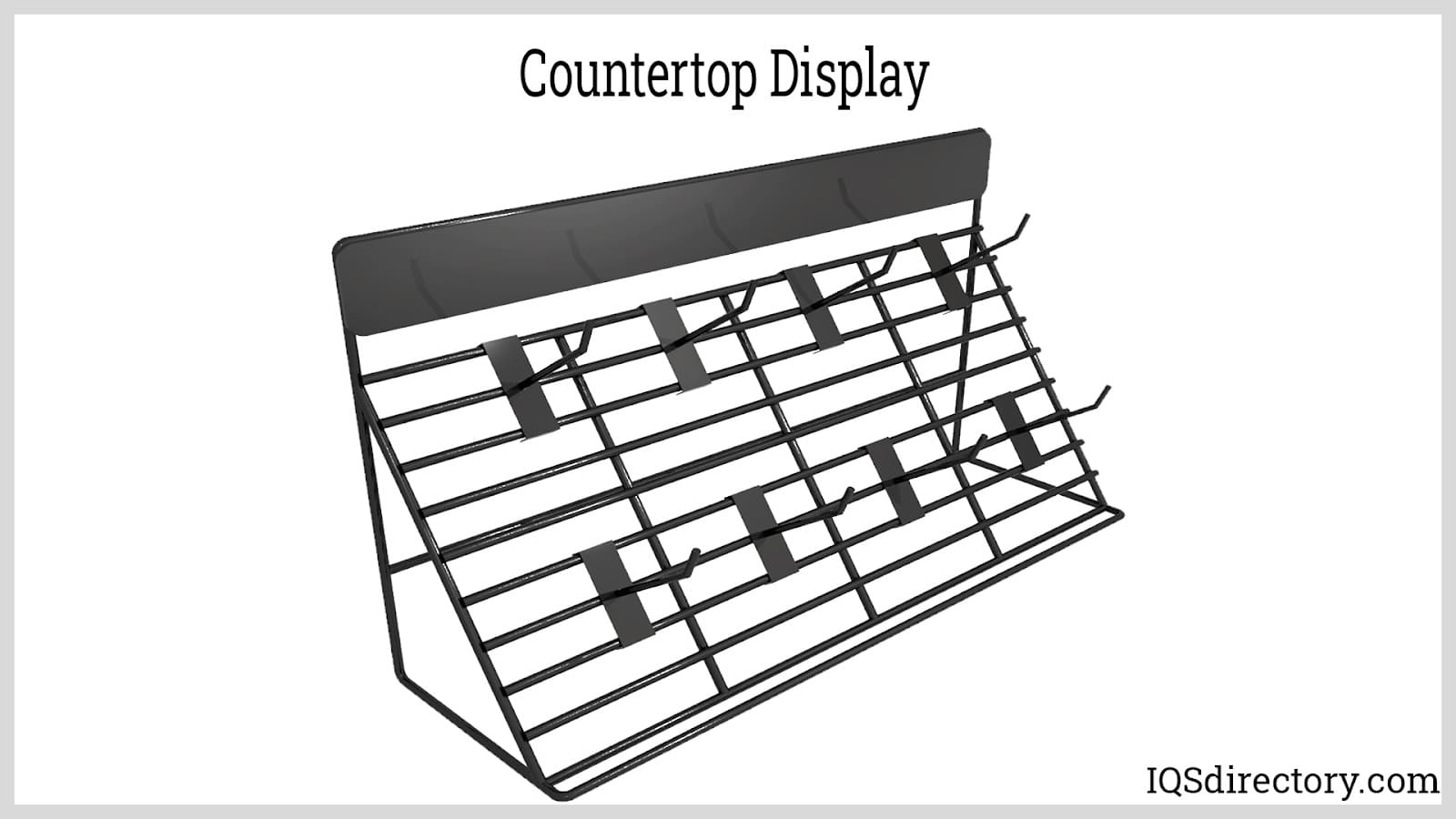

Merchandising Displays

They are the go-to wire displays for many retailers. Adding to their high affordability and durability, these commercial wire displays offer many designs for all types of products. These displays cater to products like pastries, bottles, and more with their switchable shelving. Most of them have rolling casters making them mobile. Countertop forms are applied in holding small items. Found near the point of buying counters, these alluring wire displays often provide a significant amount of profits for the business owners. Many of these displays also rotate, and are good for cards.

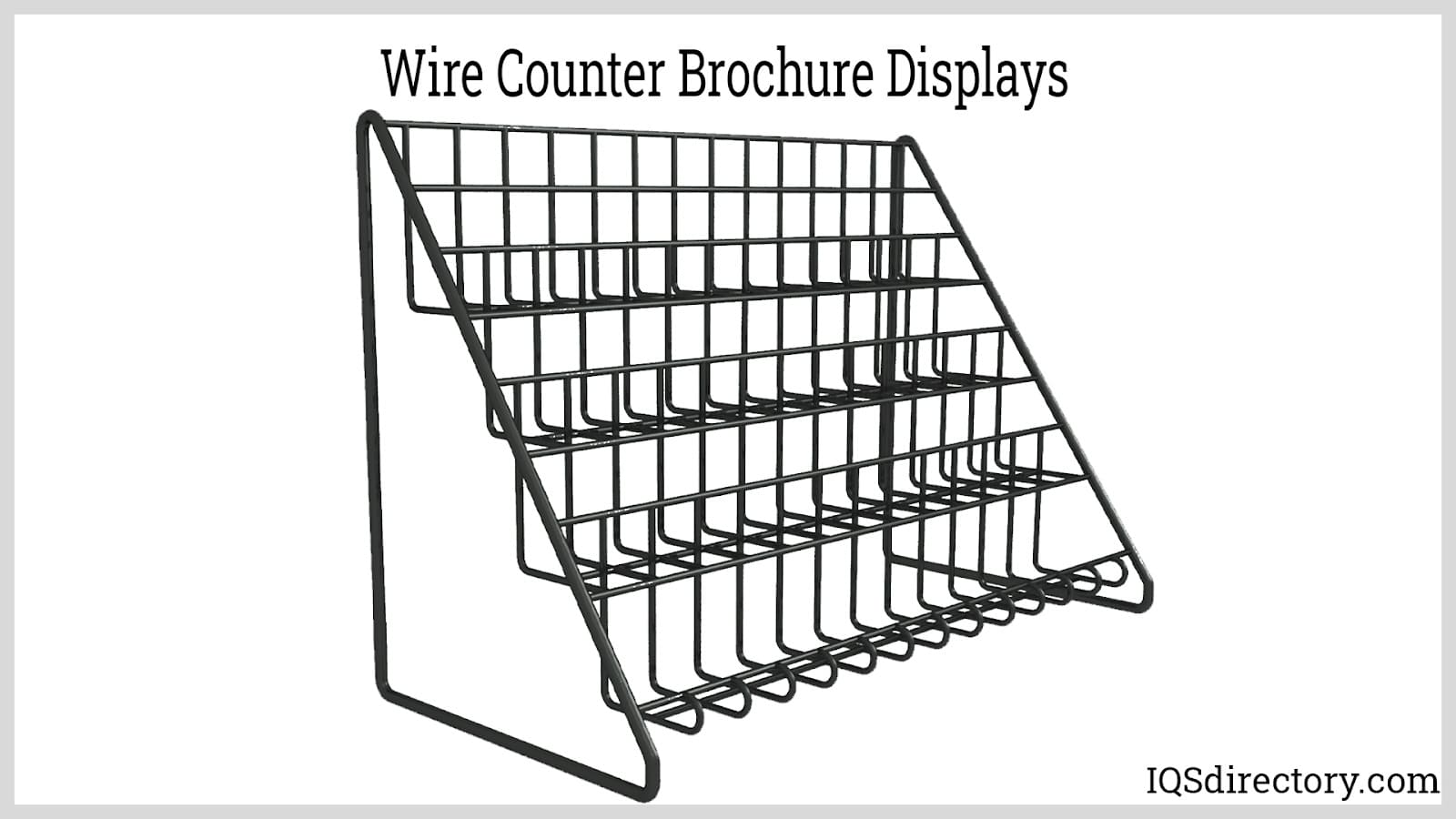

Literature Stands

They hold all kinds of magazines and provide items for sale or pamphlets in waiting rooms. The wire-frame structure helps with visibility from all directions. Countertop stands are simply smaller styles of floor variations, and are available in single-pocket or multiple-pocket designs. Tabletop displays keep areas clutter-free by providing reading material for people to take and read elsewhere.

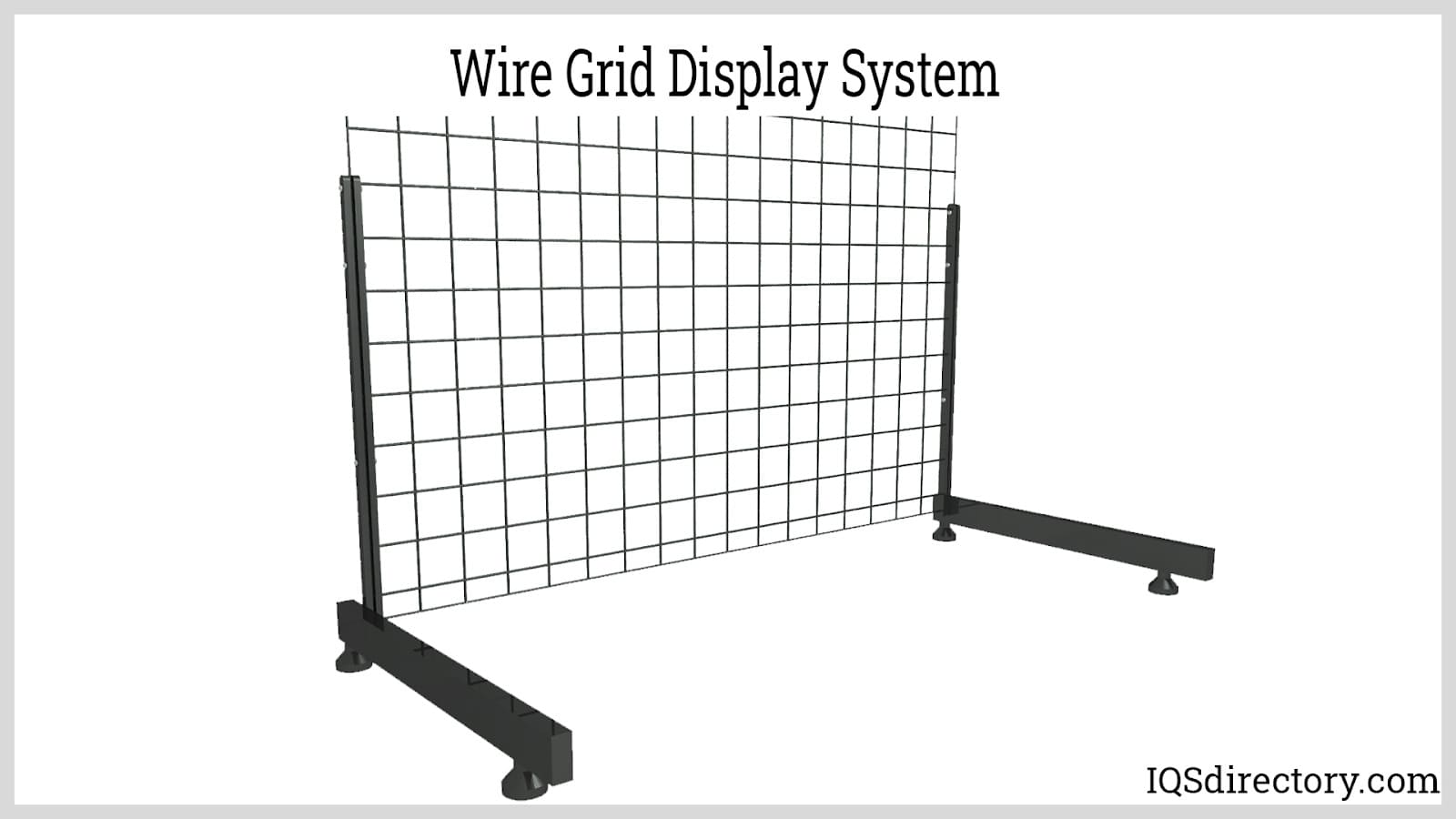

Grid-Wall Fixtures

These fixtures are found in retail store displays. They have one design similar to a slat wall, but are lighter and more affordable. Grid-wall wire displays provide wall mounting or floor options. Many extras are available, including hanging hooks and baskets, to completely customize floor layouts and highlight many products.

Art-Display Fixtures

These are the same as grid walls. They have similar frame designs, they’re very light, and great for outdoor galleries and art festivals. Their modular design allows for custom displays, with simple pins locking panels together. They are portable, inexpensive, and are compatible with grid-wall hanging accessories.

Clothes Displays

A clothes display is a wire rail used in putting clothing on display in stores. Folding clothes-wire displays are easy to move and store, making them good for various retail applications in clothing stores.

Applications of Wire Displays

Wire displays allow businesses to show informational materials or products they are involved with. A wire display near a store’s entrance, or on their counters, may provide their customers with informational pamphlets or advertising circulars. These could have marketing contents about the business, or other necessary details to inform their customers. Wire displays differ in structure; some are rotational with circular stands and others are fixed. They are also used in displaying products in retail stores and encourage impulse-buying by making products more accessible.

Advantages of Wire Displays

Versatile – Wire displays can integrate panels which can be added when there is a need. Fixed components may be reorganized to produce new or extra inventory.

Durable – High-quality wires are used to manufacture them, hence they have prolonged quality even after heavy use. They do not bend or break from the weight of products.

Economical – Wire displays offer great value and quality. Additionally, their durability makes wire displays a great, economic investment.

Easy-to-Clean – Wire displays protect items from damage. The open structure of wire displays eliminates dust collection on the displays, which can also be easily wiped.

Accessible – Wire displays in retail shops, especially near countertops and cash registers, encourage people to buy products impulsively because items are easy to pick at arm’s reach.

Choosing the Right Wire Display Supplier

To make sure you have the most positive outcome when purchasing wire displays from a wire display supplier, it is important to compare at least 4 to 5 suppliers using our wire display directory. Each wire display supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each wire display company website using our patented website previewer to get an idea of what each company specializes in and then use or simple RFQ form to contact multiple wire display companies with the same form.

Cold Headed Parts

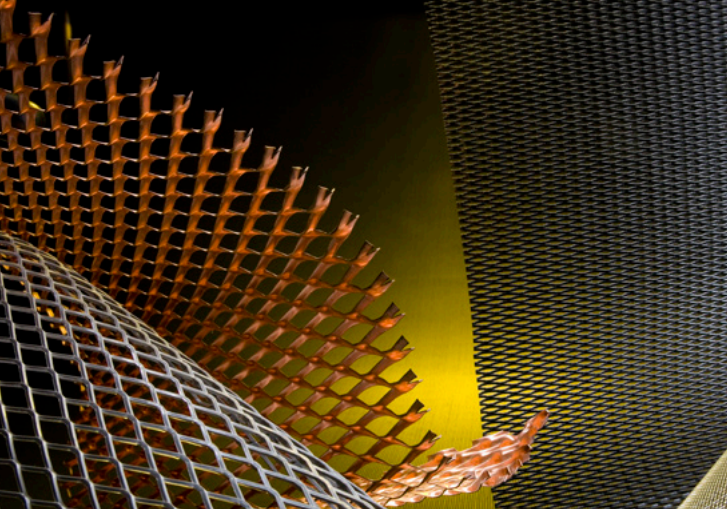

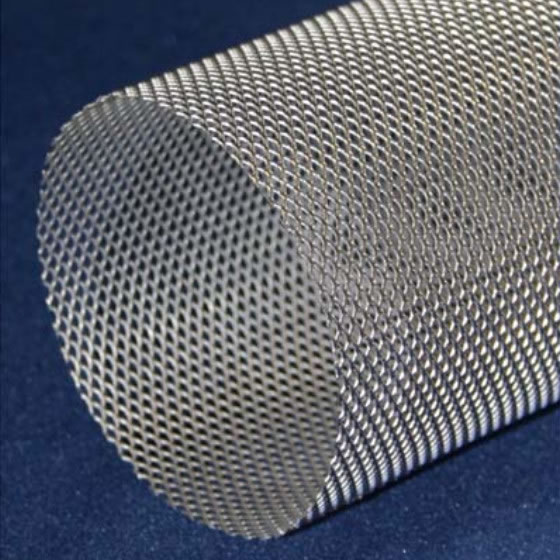

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

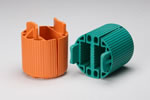

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services