Gilbert Spring Corporation

Gilbert Spring CorporationRequest A Quote

Chicago, ILWelcome to Gilbert Spring Corporation, your trusted partner for custom wire forms. With our state-of-the-art machinery and expertise, we specialize in producing wire forms with unique shapes and designs while minimizing the need for costly secondary operations. At Gilbert Spring Corporation, we understand that each customer has unique requirements for their wire forms. Our advanced manufacturing capabilities, coupled with our skilled team, allow us to create wire forms in a variety of shapes, sizes, and designs. Whether you need simple hooks and clips or complex wire assemblies, we have the expertise to deliver high-quality products that meet your specific needs. Our commitment to using state-of-the-art machinery sets us apart. We leverage cutting-edge technology in our manufacturing processes to ensure precision and consistency in every wire form we produce. This not only enhances the quality of our products but also allows us to offer cost-effective solutions to our customers. Wire forms find applications in various industries, and we cater to a wide range of sectors. Our wire forms can be found in industries such as point of purchase, lawn and garden, architectural/construction, machinery components, and many other products. We have the knowledge and experience to create wire forms that meet the specific demands of these industries, ensuring optimal performance and durability. At Gilbert Spring Corporation, we prioritize customer satisfaction. We work closely with our clients to understand their unique requirements and offer tailored solutions. Our skilled team of engineers and technicians collaborates with you throughout the design and production process to ensure that the wire forms we manufacture meet your expectations and specifications. One of our key advantages is our ability to fabricate wire forms from a wide range of wire diameters. We can work with wire ranging from 0.008 inches to 0.250 inches in diameter, catering to diverse needs and applications. Additionally, we can work with wires of any temper, providing flexibility and versatility in our manufacturing capabilities. Quality is at the core of everything we do at Gilbert Spring Corporation. We maintain stringent quality control measures throughout our manufacturing process to ensure that every wire form leaving our facility meets the highest industry standards. Our commitment to quality extends to using high-grade materials and employing skilled craftsmanship in every aspect of production. Contact Gilbert Spring Corporation today to discuss your wire form requirements. Our dedicated team is ready to assist you, providing personalized attention and reliable solutions. Experience the Gilbert Spring Corporation difference, where cutting-edge technology, expertise, and exceptional service come together to deliver custom wire forms that meet your specific needs and industry standards.

Cold Headed Parts

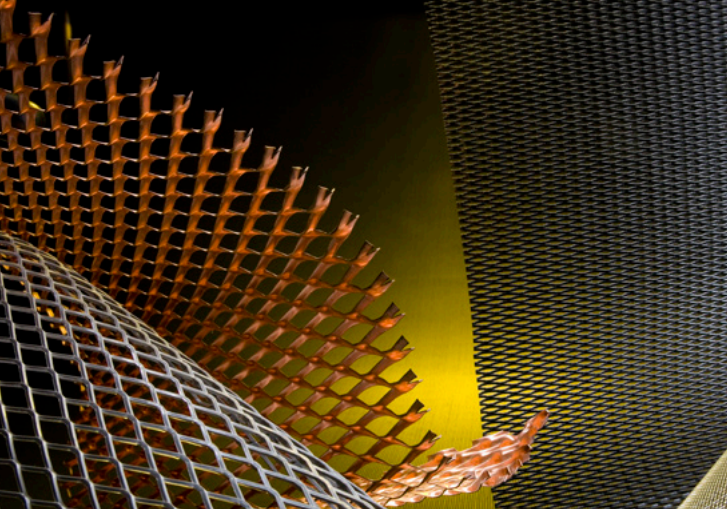

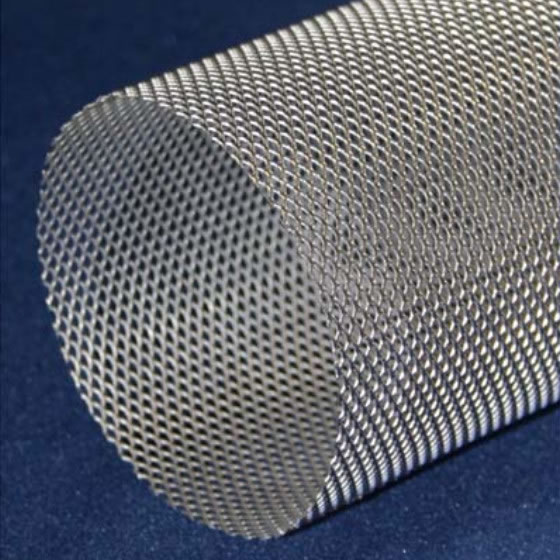

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services