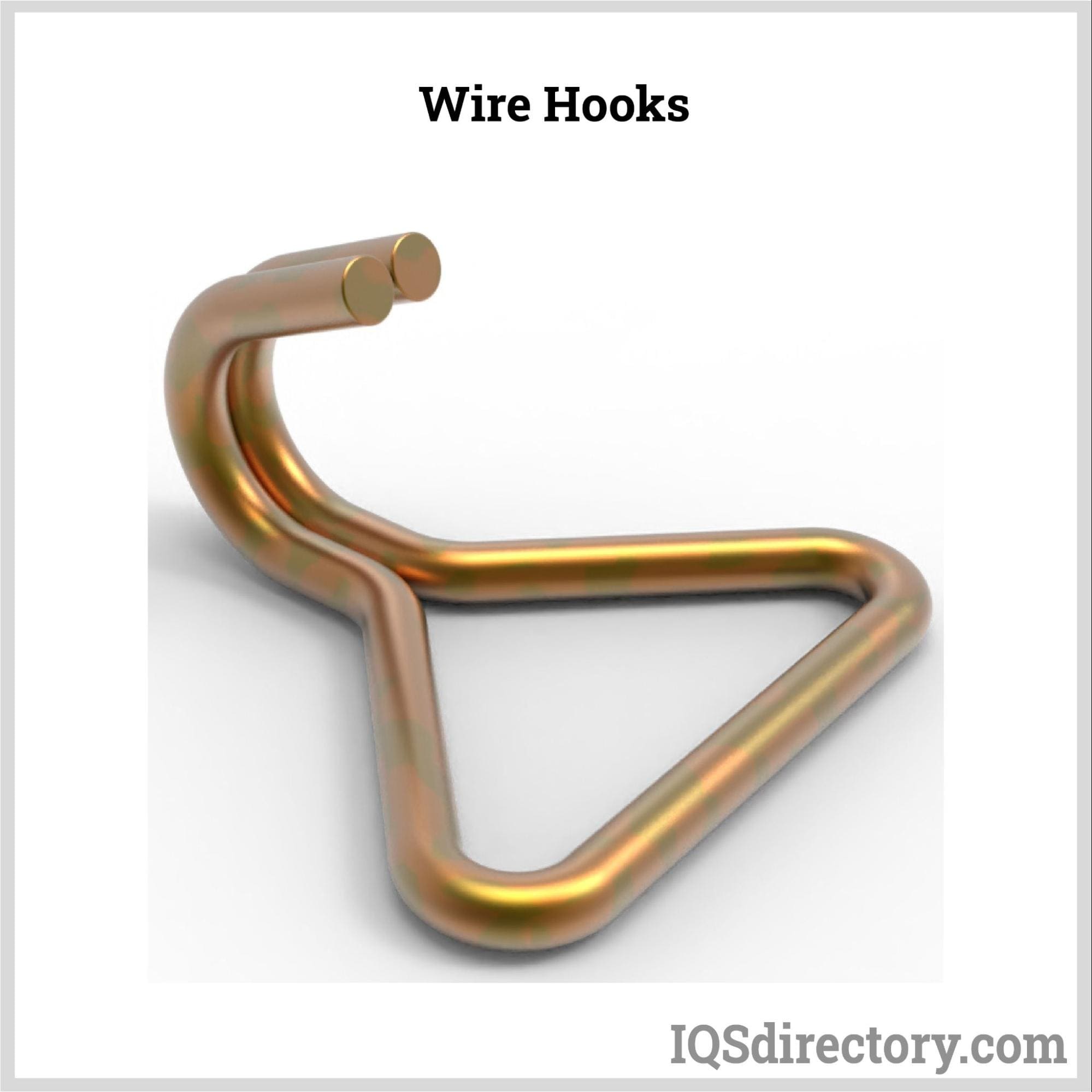

Wire Hooks

A hook is a piece of hardware made of an extended piece of material containing a bent end portion. This area is utilized to clamp, hang, or hold another object. One end of the hook is sharp for a variety of purposes so that it can pierce other materials and hold them using the curved or indented portion. Type, length, wire diameter, and bend diameter are the criteria used to define a wire hook. There are several uses for wire hooks. Hooks come in various designs. Read More…

Acme Wire Products provides close tolerance wire fabrications using steel and stainless steel. Customized applications include a wide range of wire forms for many different applications. Acme works with wire from .050 to .500 diameter.

CUSTOM "Spring & Wire Form Specialists" - Ace Wire Spring & Form incorporates the latest CNC equipment technology to manufacture compression, extension, torsion springs, complex wire forms, and spring assemblies. We offer consistent quality, lower costs, on-time deliveries, and Design Engineering Assistance. Range from prototypes to long production runs - Family owned & operated since ...

Apex Spring & Stamping is a certified minority owned company that manufacturers springs, stampings, wire forms, clips, and fasteners. Our core industries include automotive, office furniture, medical, recreational, consumer goods, and appliances. We also specialize in value added assembly and prototyping. Our engineering team will ensure your part is both functional and cost-effective. IATF 16949 ...

Smith & Richardson, Inc. is a leading provider of precision machining services, offering an extensive range of capabilities including CNC Swiss machining, Wire EDM machining, vertical and horizontal machining, CNC milling, CNC turning, assembly services, and more. With a strong commitment to quality and innovation, we serve the medical, aerospace, casting, and automotive industries, delivering...

At Elyria Spring & Specialty, LLC, we are proud to offer a wide array of high-quality wire forms and comprehensive solutions tailored to meet the diverse needs of our valued customers. With a rich history of expertise and a steadfast commitment to excellence, we have established ourselves as a trusted leader in the wire forming industry. Our product portfolio encompasses a diverse range of wire...

Here at Anderson Quality Spring Manufacturing, Inc., we take great pride in our position as a leading provider of wire forms, offering a comprehensive range of products, services, and capabilities to meet the diverse needs of our valued clientele. With our unwavering commitment to excellence and extensive expertise in wire forming technology, we stand ready to deliver innovative solutions that...

At New England Spring, we pride ourselves on being a premier provider of high-quality wire forms and comprehensive solutions tailored to meet the diverse needs of our valued customers. With decades of experience and a steadfast commitment to excellence, we have established ourselves as a trusted leader in the wire forming industry. Our product portfolio encompasses a wide range of wire forms,...

More Wire Hook Manufacturers

While other hook variations are named after their intended purpose, such as gate hooks, fish hooks, rope binding hooks, and others, S-hooks, J-hooks, and C-hooks are named after their appearance. Various industries, including plumbing, hardware, parts manufacture, fishing, design, and others, commonly use these adaptable objects known as wire hooks. For wire displays, hooks are frequently decorative and expertly crafted. Objects such as clothing, caps, and even food are arranged and displayed on such hooks, which may be mounted to the wall or otherwise suspended.

Types of Wire Hooks

Wire-Hanging Hooks and Fittings

Wire end fittings are height-adjustable components (hooks and loops) designed for use with 1.5 mm hanging wires and ceiling fixings. Each fitting has a self-locking mechanism with an integrated release button for simple height adjustment. Installation is quick and dependable since specific crimping tools are not needed.

Cable Safety Hooks

A long service life of over 25 years of active usage in heavy industries is guaranteed by the fire retardant, non-conductive, and extremely high UV resistance of cable safe safety hooks. Cable hooks are appropriate for bundled cables because they have holes in both ends that allow the user to wrap a cable tie around them to secure and fix them. Cable safe S-hooks assist with cable management and housekeeping. They are simple to use and quickly clear cables and wires.

Four sizes are available: 6", 9", 12", and 15" [about 15, 23, 30, and 38 cm]. These hooks don't conduct heat or electricity.Cable safety hooks are durable and have been used actively in heavy industries for more than 25 years. It is possible to receive these hooks with the manufacturer’s name engraved in the cable hook or in a distinctive color. It's important to consider the hook’s material, size, weight, wire density, and finishing for a specific application

Classification of Wire Hooks

There are various hook models available on the market, depending on their purpose.

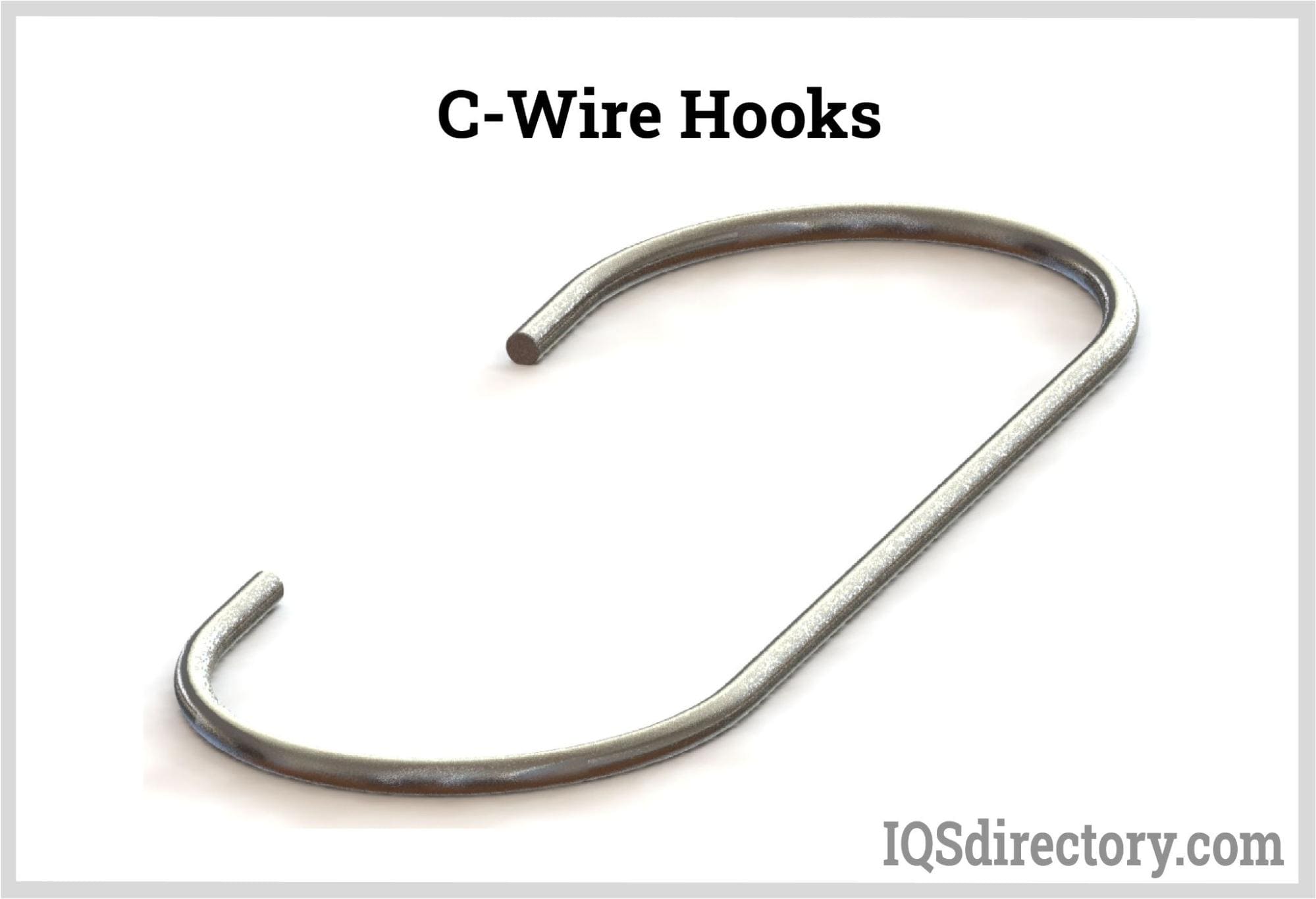

- C-hooks are excellent for broader components or parts with multiple types of different thicknesses. Round ends on C-style hooks make them simple to install on crossbars and profiles with rounded edges. In addition, these hooks can be combined to daisy-chain several objects to the desired length.

- S-hooks resemble C-hooks except that they feature a bottom extension that is bent in the opposite direction. Metal S-shaped hooks have rounded edges ideal for hooking on railways, pipes, and other similar surfaces.

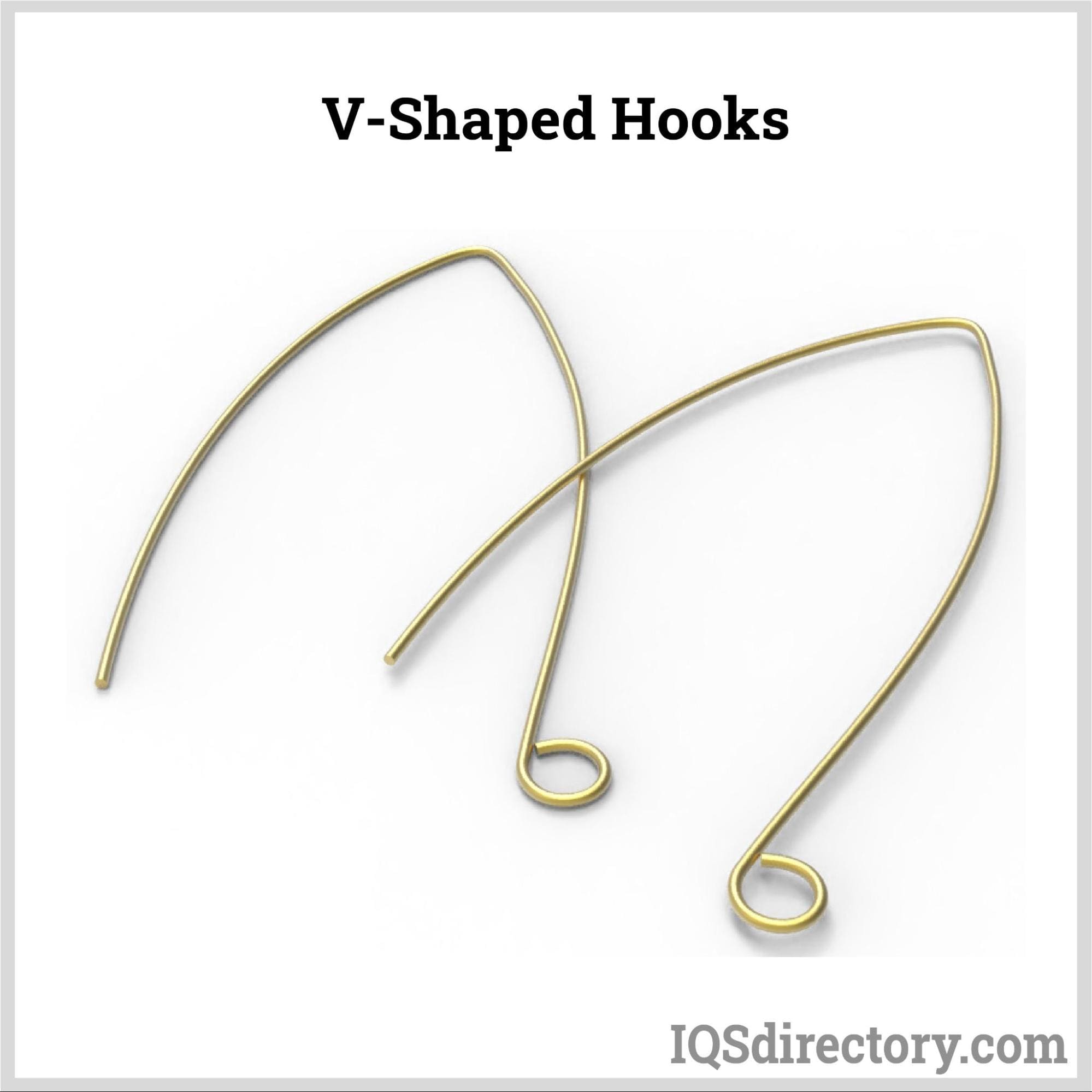

- V-hooks: This hook's greatest distinguishing attribute is its "V" form, which increases its capacity to hold onto an item for longer than a C-style hook. The "V" bottom also enables the suspended section to consistently rest in the same spot. When parts are strung on these hooks, they are more stable on the line and will keep their orientation better.

- J-hooks are a great all-purpose style of wire hook. They can be observed on many ratchet strap applications, including motorcycle straps, utility trailer straps, wire support systems, and more.

- CV-hooks are a hook that combines the advantages of both a "V" and a "C" style hook in terms of simplicity of usage. Both conventional and round-stock conveyor systems can use it.

Hooks that are not intended for a particular application are called utility hooks. There are many designs available in various forms with various threads, unique coatings, etc. Rubber rope hooks, hanger hooks and shelving hooks are a few examples. For highly specific uses, manufacturers also create additional types of wire hooks in addition to those already listed.

To satisfy the demands of any sector, pick a manufacturer that offers a full array of custom wire hooks. To find the best supplier, search for those with the equipment and know-how to make wire-bending goods with various wire diameters, hook forms, materials, surface coatings, etc.

Choosing the Right Wire Hook Manufacturer

To make sure you have the most productive outcome when purchasing wire hooks from a wire hook manufacturer, it is important to compare at least 4 manufacturers using our wire hook directory. Each wire hook manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each wire hook business website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple wire hook businesses with the same message.

Cold Headed Parts

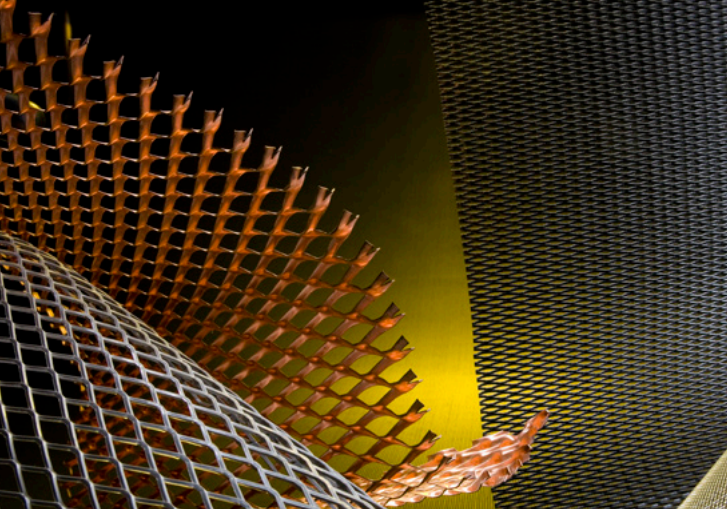

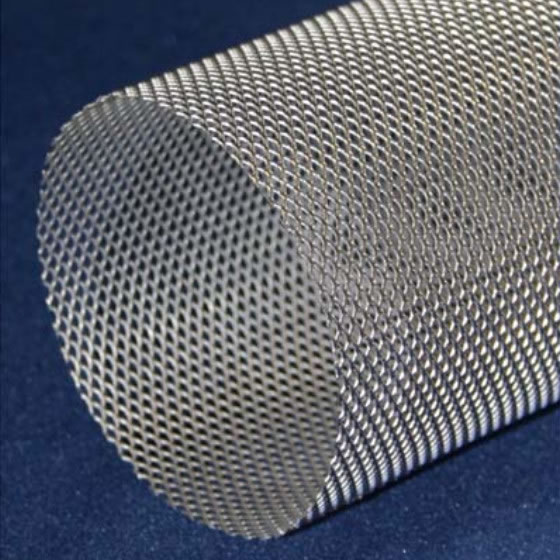

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services