Wire newspaper racks are a common sight in public places such as streets, shopping malls, and airports. They provide a convenient means of displaying and distributing newspapers and other printed materials to the public. In this article, we will explore the creation of wire newspaper racks, as well as variations in their creation, considerations regarding wire newspaper racks, and the benefits associated with them.Read More…

Acme Wire Products provides close tolerance wire fabrications using steel and stainless steel. Customized applications include a wide range of wire forms for many different applications. Acme works with wire from .050 to .500 diameter.

CUSTOM "Spring & Wire Form Specialists" - Ace Wire Spring & Form incorporates the latest CNC equipment technology to manufacture compression, extension, torsion springs, complex wire forms, and spring assemblies. We offer consistent quality, lower costs, on-time deliveries, and Design Engineering Assistance. Range from prototypes to long production runs - Family owned & operated since ...

Apex Spring & Stamping is a certified minority owned company that manufacturers springs, stampings, wire forms, clips, and fasteners. Our core industries include automotive, office furniture, medical, recreational, consumer goods, and appliances. We also specialize in value added assembly and prototyping. Our engineering team will ensure your part is both functional and cost-effective. IATF 16949 ...

Smith & Richardson, Inc. is a leading provider of precision machining services, offering an extensive range of capabilities including CNC Swiss machining, Wire EDM machining, vertical and horizontal machining, CNC milling, CNC turning, assembly services, and more. With a strong commitment to quality and innovation, we serve the medical, aerospace, casting, and automotive industries, delivering...

At Elyria Spring & Specialty, LLC, we are proud to offer a wide array of high-quality wire forms and comprehensive solutions tailored to meet the diverse needs of our valued customers. With a rich history of expertise and a steadfast commitment to excellence, we have established ourselves as a trusted leader in the wire forming industry. Our product portfolio encompasses a diverse range of wire...

Here at Anderson Quality Spring Manufacturing, Inc., we take great pride in our position as a leading provider of wire forms, offering a comprehensive range of products, services, and capabilities to meet the diverse needs of our valued clientele. With our unwavering commitment to excellence and extensive expertise in wire forming technology, we stand ready to deliver innovative solutions that...

At New England Spring, we pride ourselves on being a premier provider of high-quality wire forms and comprehensive solutions tailored to meet the diverse needs of our valued customers. With decades of experience and a steadfast commitment to excellence, we have established ourselves as a trusted leader in the wire forming industry. Our product portfolio encompasses a wide range of wire forms,...

More Newspaper Rack Manufacturers

Creating Wire Newspaper Racks

The process of creating wire newspaper racks involves several steps. The first step is to create a design that meets the requirements of the newspaper publisher or distributor. This design will dictate the size, shape, and components of the rack.

Once the design is finalized, the wire forms are prepared. This involves cutting and bending the wire to the desired lengths and angles using wire cutters and bending tools. The wire forms are then assembled using welding or brazing techniques.

Welding is the process of melting the wire at the joints and fusing it together using a filler material. This creates a strong bond that is resistant to bending and twisting. Brazing is similar to welding but involves using a lower-temperature filler material that is melted and allowed to flow into the joints. This creates a strong bond that is more flexible and allows for some movement.

After the wire forms are assembled, they are finished using a variety of techniques, such as powder coating or plating. Powder coating involves applying a layer of dry powder to the wire forms and then heating them to create a hard, durable finish. Plating involves coating the wire forms with a layer of metal, such as chrome or nickel, to improve their appearance and durability.

Then, the components of the wire newspaper rack, such as the dividers, shelves, and base, are added to the wire forms. These components are attached using welding or brazing techniques and are designed to fit seamlessly into the overall design of the rack. The frame provides the structure for the rack and is usually made from thicker wire. The dividers separate the newspapers and prevent them from falling over, while the shelves hold the newspapers in place. Finally, the base provides stability and prevents the rack from tipping over.

Variations in Wire Newspaper Racks

There are several variations in wire newspaper racks that can be customized to fit the specific needs of a newspaper publisher or distributor. These variations, among others, include the form and type of wire material used in the rack.

Form of Wire Newspaper Racks

Wire newspaper racks come in a variety of forms, including wall-mounted racks, freestanding racks, and tabletop racks. Wall-mounted racks are attached to a wall or other vertical surface using screws or other fasteners. Freestanding racks are designed to stand on their own and are usually heavier and more stable than wall-mounted racks. Tabletop racks are smaller in size and are designed to be placed on a table or other horizontal surface.

Type of Wire Material Used

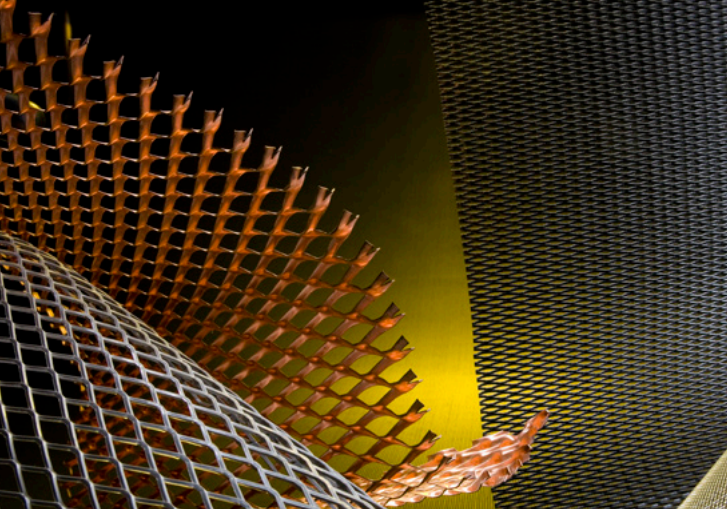

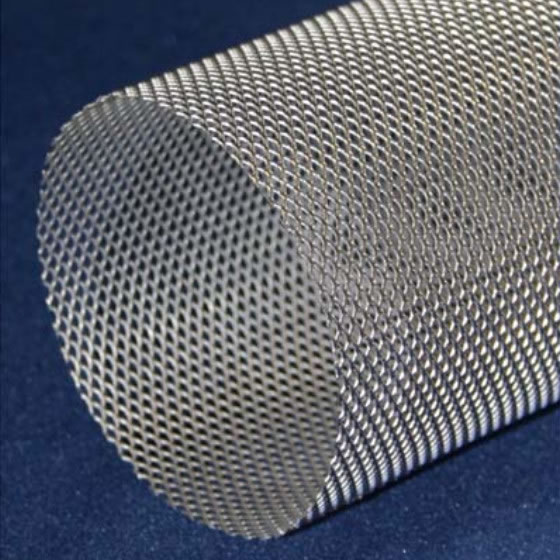

Wire newspaper racks can be made from a variety of materials, including stainless steel, aluminum, and copper. Each material has its own unique properties that make it suitable for certain applications. Stainless steel is commonly used for outdoor racks because of its resistance to weather conditions, corrosion, and rust. Aluminum is often used for indoor racks because of its lightweight and cost-effectiveness. Copper is a less common material but can be used for indoor racks because of its aesthetic appeal and durability.

Additional Variables

Other variations in wire newspaper racks include the size, shape, and number of shelves, dividers, and compartments. These variations can be customized to meet the specific needs of a newspaper publisher or distributor, and can also be adjusted to fit the available space in a particular location. In addition to these variations, some wire newspaper racks are designed to be collapsible or foldable, making them easier to transport and store. This can be particularly useful for publishers or distributors who need to move their racks frequently or who have limited storage space.

Considerations Regarding Wire Newspaper Racks

There are some factors to consider when purchasing wire newspaper racks. One limitation is their susceptibility to damage and weather conditions. Outdoor racks can become damaged due to exposure to rain, snow, and wind. Additionally, vandalism is a common problem with outdoor racks, and they can be costly to repair or replace.

Benefits of Wire Newspaper Racks

Despite their potential limitations, wire newspaper racks have many benefits, including:

Durability and Longevity

Wire newspaper racks are designed to withstand daily wear and tear and are built to last for years. They are resistant to corrosion and rust, making them ideal for outdoor use.

Easy to Clean

Wire newspaper racks are easy to clean and maintain. They can be wiped down with a damp cloth or cleaned with a mild soap and water solution.

Easy to Install

Wire newspaper racks are typically easy to install and can be mounted on a wall or placed on a stand. This makes them a convenient and practical solution for newspaper publishers or distributors.

Visibility

Wire newspaper racks are designed to showcase newspapers and other publications, making them easily visible to the public. This can increase sales and distribution for publishers and distributors.

Customizability

Wire newspaper racks can be customized to fit the specific needs of a publisher or distributor. This includes size, shape, and number of shelves, as well as the type of wire material used.

Space Efficiency

Wire newspaper racks are typically designed to take up minimal space, making them ideal for small locations. This can allow for more newspapers to be displayed in a smaller area.

Sustainability

Wire newspaper racks are environmentally friendly and can be recycled at the end of their lifespan. This makes them a sustainable option for newspaper publishers and distributors who are looking to reduce their environmental impact.

In addition to these benefits, wire newspaper racks can also be used for other purposes beyond displaying and distributing newspapers. They can be used to showcase magazines, brochures, or other promotional materials. They can also be used in retail settings to display small items or products.

Choosing the Right Wire Newspaper Rack Manufacturer

To ensure you have the most productive outcome when purchasing wire newspaper racks from a wire newspaper rack manufacturer, it is important to compare several companies using our directory of wire newspaper rack manufacturers. Each wire newspaper rack manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each wire newspaper rack business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple wire newspaper rack companies with the same form.

Cold Headed Parts

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services