Fan guards create a physical barrier around rotating fan blades to prevent unintentional contact with fingers or other objects. Typically, plastic or metal wire is used to make them. The shape of the fan blades themselves and the level of accessibility needed determine the different fan guards produced. Fan guards are made to reduce noise while maximizing airflow. In addition, some fan guard systems contain filter media to help stop dust and other contaminants from entering enclosures through the fan. The mounting options include snap-on variants that attach directly by applying a pressing force and through-hole ones that are fastened with a screw or bolt. Read More…

Acme Wire Products provides close tolerance wire fabrications using steel and stainless steel. Customized applications include a wide range of wire forms for many different applications. Acme works with wire from .050 to .500 diameter.

CUSTOM "Spring & Wire Form Specialists" - Ace Wire Spring & Form incorporates the latest CNC equipment technology to manufacture compression, extension, torsion springs, complex wire forms, and spring assemblies. We offer consistent quality, lower costs, on-time deliveries, and Design Engineering Assistance. Range from prototypes to long production runs - Family owned & operated since ...

Apex Spring & Stamping is a certified minority owned company that manufacturers springs, stampings, wire forms, clips, and fasteners. Our core industries include automotive, office furniture, medical, recreational, consumer goods, and appliances. We also specialize in value added assembly and prototyping. Our engineering team will ensure your part is both functional and cost-effective. IATF 16949 ...

Smith & Richardson, Inc. is a leading provider of precision machining services, offering an extensive range of capabilities including CNC Swiss machining, Wire EDM machining, vertical and horizontal machining, CNC milling, CNC turning, assembly services, and more. With a strong commitment to quality and innovation, we serve the medical, aerospace, casting, and automotive industries, delivering...

At Elyria Spring & Specialty, LLC, we are proud to offer a wide array of high-quality wire forms and comprehensive solutions tailored to meet the diverse needs of our valued customers. With a rich history of expertise and a steadfast commitment to excellence, we have established ourselves as a trusted leader in the wire forming industry. Our product portfolio encompasses a diverse range of wire...

Here at Anderson Quality Spring Manufacturing, Inc., we take great pride in our position as a leading provider of wire forms, offering a comprehensive range of products, services, and capabilities to meet the diverse needs of our valued clientele. With our unwavering commitment to excellence and extensive expertise in wire forming technology, we stand ready to deliver innovative solutions that...

At New England Spring, we pride ourselves on being a premier provider of high-quality wire forms and comprehensive solutions tailored to meet the diverse needs of our valued customers. With decades of experience and a steadfast commitment to excellence, we have established ourselves as a trusted leader in the wire forming industry. Our product portfolio encompasses a wide range of wire forms,...

More Fan Guard Manufacturers

Materials and Forming Processes Used

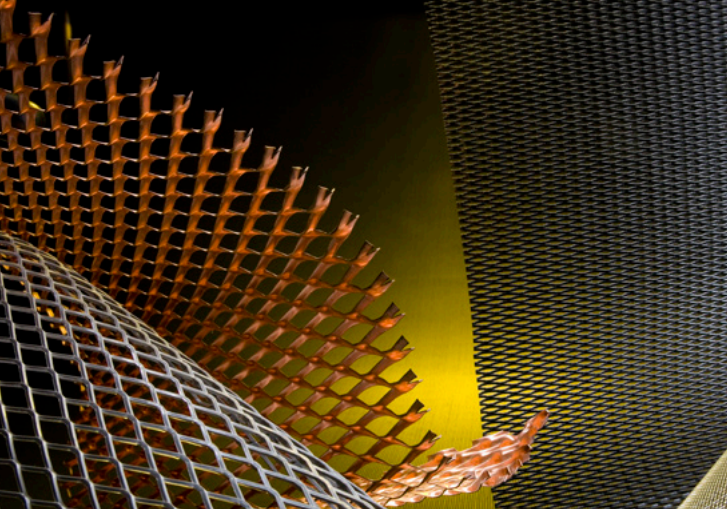

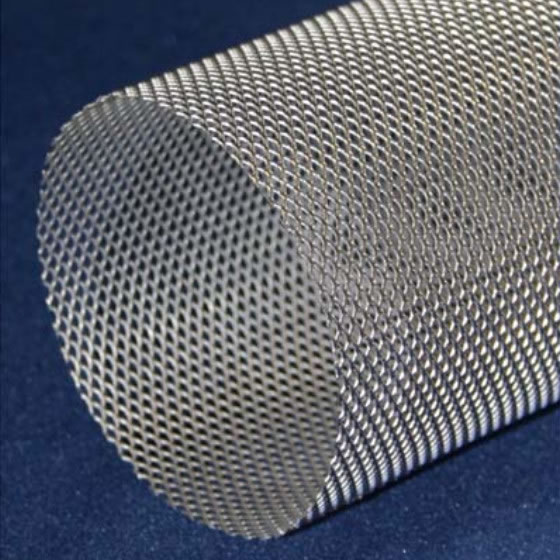

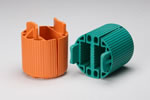

Fan guards can have two-dimensional or three-dimensional geometries developed for them. Metal wire fan guards are made by a process that includes cutting, bending, welding, and surface preparation. Fabrication techniques for metal fan guards include automated wire mesh welding and CNC wire coil shaping. Stainless steel, aluminum alloy, and low-carbon steel are all acceptable materials for metal wire.

Injection molding is a commonly used method for producing plastic fan guards from nylon, polybutylene terephthalate (PBT), and acrylonitrile butadiene styrene (ABS). UL94V-0 and other fire resistance standards are frequently found on plastic fan shields.

Fan Guard Wire Protective Treatments

Different types of stainless steel or brilliant basic steel metal wire are commonly resistance or arc welded into various forms, from circular to rectangular, to specific configurations and sizes, depending on their intended application, to create fan guards. After that, protective coatings like chrome plating, zinc plating, powder coating, and UV-resistant polyester or urethane finishes can be applied to the finished product. Metal fan guards are frequently found with coatings and surface treatments that protect against corrosion. These consist of the following:

- Polished zinc coating or bright nickel chrome plating

- Chromate treatment with gold

- Anodizing

- Heat therapy

- Epoxy powder coating annealing

- Coating with a polymer powder

- Plastic (PVC, PE) dipping

Plastic fan guards, as mentioned above, receive their protection from the choice of plastic material used to meet a specific application.

Design and Customization of Fan Guards

Fan guards often feature an outside ring, concentric ribs, a mounting hole in the center, and some brackets or fasteners around the outside to attach to the fan or motor. They can have bespoke shapes and configurations and be flat, domed, with flat or bowed sides. Several different fan guard configurations are available including:

- Circular rectangle-shaped dome

- Taper-sided

- Wire spiral

Special designs are available by contacting fan guard manufacturers. Almost any size or shape of fan guard may be made to order by the majority of manufacturers, who also carry a variety of combinations and sizes.

Safety requires the use of fan guards. They can be built of various plastic, steel, or other metals and come in various sizes and layouts. Metal wire fan guards can also be coated, polished, and anodized in various ways, depending on the application and for aesthetic reasons. For instance, a waterproof coating or other finish on the metal exterior or outdoor fan guards can prevent rust, oxidation, and material degradation from exposure to the environment over time.

These fan accessories can also be powder coated or plated to prevent rust and damage. Urethane or polyester can offer UV protection and stop material deterioration for fans that are used outdoors. Cosmetic finishes might be black, nickel chrome, or another color. In commercial and industrial environments, fan guards are frequently required to ensure adherence to safety requirements, such as those imposed by the Occupational Safety and Health Administration.

Fan-Guarding Functions

- Make use of time: keep dust out of the fan, which will shorten its lifespan.

- As a safety precaution to avoid having the fan touch your fingertips. Think about the effects of a 600-rpm fan blade contacting your fingers.

- Prevent items from entering; shield the fan from being struck by large objects and guard against sucking in enormous but insignificant masses

- Control the air duct: Because the fan is self-cooling, it will blow the wind cover to the end along the space between it and a heat sink, removing heat from the heat sink. Without a guard, the fan's wind has no direction and does a terrible job of dissipating heat.

Applications

Fan guards can be utilized for fans in a variety of situations, such as:

- Electrical cooling fans cool electronic devices, such as computer case fans. Sizes in the 40, 60, 80, 92, 120, and 140mm range are typical.

- Industrial exhaust fans that remove air that may be contaminated with smoke, toxic gases, fumes, and other unfavorable elements from a structure or workspace.

- Heat exchangers, cooling towers, and process dryers are examples of large-scale industrial equipment that use process cooling fans.

- Pneumatic fans for material handling are used to transport granular materials, such as grains, powders, and pellets of plastic resin, between storage bins and production machinery.

- HVAC (heating, ventilation, and air conditioning) fans that circulate air in structures and other enclosed spaces, such as plenum and duct fans.

Choosing the Right Fan Guard Supplier

To make sure you have the most beneficial outcome when purchasing fan guards from a fan guard supplier, it is important to compare at least 4 to 5 companies using our list of fan guard suppliers. Each fan guard supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each fan guard company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple fan guard companies with the same form.

Cold Headed Parts

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services