Wire forms are any shapes or parts that have been fabricated via the manipulation of wire, i.e. any processes that alter wire shape, like wire cutting, wire bending and heat treating. Read More…

Acme Wire Products provides close tolerance wire fabrications using steel and stainless steel. Customized applications include a wide range of wire forms for many different applications. Acme works with wire from .050 to .500 diameter.

CUSTOM "Spring & Wire Form Specialists" - Ace Wire Spring & Form incorporates the latest CNC equipment technology to manufacture compression, extension, torsion springs, complex wire forms, and spring assemblies. We offer consistent quality, lower costs, on-time deliveries, and Design Engineering Assistance. Range from prototypes to long production runs - Family owned & operated since ...

Apex Spring & Stamping is a certified minority owned company that manufacturers springs, stampings, wire forms, clips, and fasteners. Our core industries include automotive, office furniture, medical, recreational, consumer goods, and appliances. We also specialize in value added assembly and prototyping. Our engineering team will ensure your part is both functional and cost-effective. IATF 16949 ...

Smith & Richardson, Inc. is a leading provider of precision machining services, offering an extensive range of capabilities including CNC Swiss machining, Wire EDM machining, vertical and horizontal machining, CNC milling, CNC turning, assembly services, and more. With a strong commitment to quality and innovation, we serve the medical, aerospace, casting, and automotive industries, delivering...

At Elyria Spring & Specialty, LLC, we are proud to offer a wide array of high-quality wire forms and comprehensive solutions tailored to meet the diverse needs of our valued customers. With a rich history of expertise and a steadfast commitment to excellence, we have established ourselves as a trusted leader in the wire forming industry. Our product portfolio encompasses a diverse range of wire...

Here at Anderson Quality Spring Manufacturing, Inc., we take great pride in our position as a leading provider of wire forms, offering a comprehensive range of products, services, and capabilities to meet the diverse needs of our valued clientele. With our unwavering commitment to excellence and extensive expertise in wire forming technology, we stand ready to deliver innovative solutions that...

At New England Spring, we pride ourselves on being a premier provider of high-quality wire forms and comprehensive solutions tailored to meet the diverse needs of our valued customers. With decades of experience and a steadfast commitment to excellence, we have established ourselves as a trusted leader in the wire forming industry. Our product portfolio encompasses a wide range of wire forms,...

More Wire Form Manufacturers

Wire Forming Applications

Wire forming stands as a versatile manufacturing technique, adept at molding wire into myriad shapes and designs tailored to diverse applications. Harnessing the inherent flexibility and robustness of wire, this method finds utility across a spectrum of industries such as automotive, aerospace, electronics, medical, and construction. Here are some common wire forming applications:

Springs

Springs, ubiquitous wire-formed products, find extensive utility across diverse industries. They serve pivotal roles in vehicle suspension systems, door locks, mattresses, mechanical contraptions, and even toys.

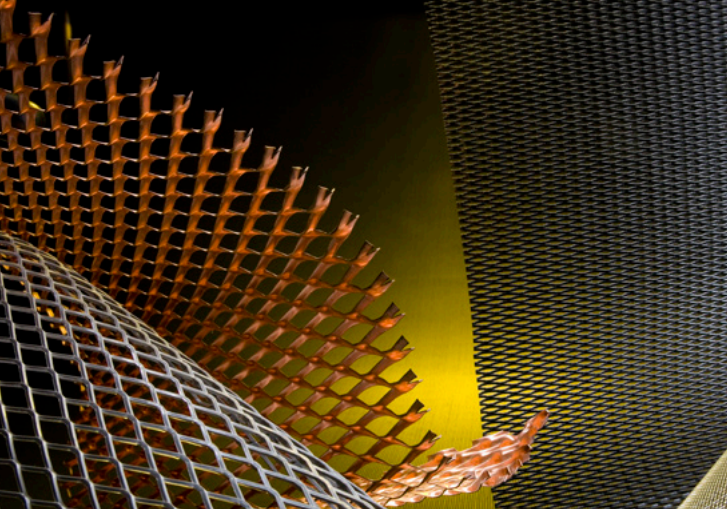

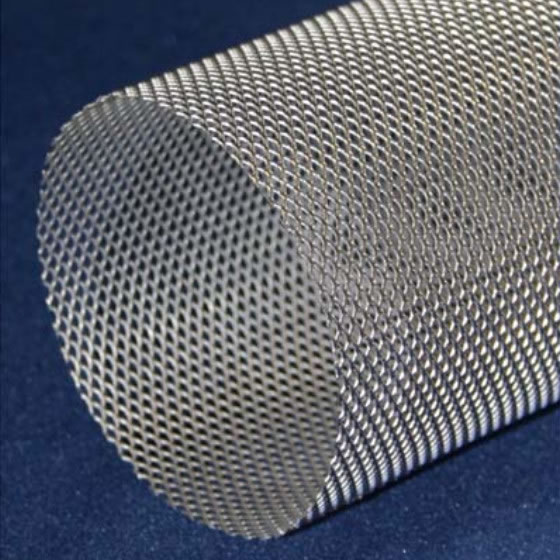

Wire Mesh and Filters

Wire mesh emerges from the intricate interweaving or welding of wires, crafting a grid-like pattern essential for myriad uses such as air and liquid filtration, protective barriers, sieving, screening, and fencing.

Wire Baskets and Racks

Wire-formed baskets and racks are extensively utilized for storage and organization across various industries, including retail, logistics, and healthcare. These structures offer clear visibility, ample ventilation, and convenient access to stored items, ensuring efficiency and ease of use.

Wire Forms for Fasteners and Connectors

Wire forming is a versatile technique used to craft various fasteners, including hooks, clips, pins, and rings. These essential components find applications across numerous industries such as construction, automotive assembly, and furniture manufacturing, among many others.

Wire-Based Displays and Fixtures

Wire forming techniques craft elegant and functional display stands, racks, and hangers for retail environments, trade shows, and exhibitions. These displays are lightweight and highly customizable, ensuring an appealing presentation of products that catches the eye.

Medical Devices

Wire forming plays a pivotal role in crafting essential medical devices, including surgical instruments, orthopedic implants, stents, catheters, and dental appliances. The wire’s inherent flexibility and biocompatibility render it ideal for these critical applications, ensuring both functionality and patient safety.

Wire Forms for Electrical Applications

Wires are crucial for transmitting electricity, and wire forming techniques are used to craft a range of electrical components including connectors, terminals, lead wires, and coil forms for transformers and motors.

Custom Wire Shapes

Wire forming enables the crafting of bespoke wire shapes tailored to meet unique application needs. This versatile process can produce intricate geometries for prototypes, artistic installations, decorative pieces, and architectural elements.

Safety and Restraints

Wire-formed products play a crucial role in safety applications, such as safety harnesses, seat belts, window restraints, and fall protection systems. These applications demand robust and dependable wire forms to guarantee the user’s safety.

Automotive Applications

Wire forming plays a crucial role in the automotive industry, shaping essential components such as seat frames, exhaust hangers, engine parts, brake and clutch systems, and wire harnesses.

Wire forming applications span a vast array of industries, showcasing its remarkable versatility. The adaptability of wire, coupled with the ingenuity of wire forming techniques, enables the creation of numerous innovative and practical solutions tailored to meet diverse requirements.

History of Wire Forming

For centuries, humans have harnessed the versatility of wire, transforming it through the ages. In ancient times, craftsmen meticulously shaped wire by hand, a skill later augmented by simple handheld tools. Among the earliest creations were exquisite pieces of jewelry, a testament to the artisans’ craftsmanship. While modern technology often automates the creation of wire jewelry, many local artisans continue to uphold the tradition, handcrafting each piece with care and precision.

The first wire mill sprouted in Great Britain in the 1600s, marking the dawn of a new era. This pioneering establishment soon inspired a wave of successors, each bringing innovative methods for crafting wire and discovering novel applications for its versatile form.

One of the most groundbreaking advancements in metal forming in the modern era is the incorporation of computer numerical control (CNC) technology. By employing CNC machines, custom manufacturers can program their forming equipment to consistently produce high-quality designs. This technology enables the creation of more precise and intricate designs than ever before, seamlessly merging the realms of custom wire forms and mass production.

Wire Materials Used In Forming

Wire forms can be crafted from a wide variety of metal materials. Among the most popular choices are steel, stainless steel, aluminum, brass, copper, and various alloys.

Steel

Among the various metals utilized in wire forming, steel, specifically carbon steel, stands out as the most prevalent choice. This high-strength alloy, predominantly composed of carbon and iron, combines remarkable tensile strength with affordability, making it an ideal material for many applications.

Stainless Steel

Stainless steel, an alloy of steel enhanced with chromium, boasts remarkable strength and durability. This addition grants it impressive resistance to rust and corrosion, as well as antibacterial properties. With 15 distinct grades available, stainless steel offers a versatile array of options to suit various needs.

Aluminum

Aluminum, a venerable metal, is celebrated for its remarkable qualities: enduring durability, robust strength, exceptional heat resistance, and steadfast resistance to rust and corrosion.

Brass

Brass, a blend of copper and zinc, is prized for its striking, gold-like luster that resists tarnishing, making it a popular choice for decorative metalwork. Additionally, its excellent thermal conductivity enhances its utility in various applications.

Copper

For millennia, humans have harnessed the power of copper, a naturally occurring element distinguished by its warm, reddish hue. This versatile metal is renowned for its exceptional ability to conduct heat and electricity while standing resilient against rust and extreme temperatures.

Wire Forming Process Details

There are a wide variety of different wire forming processes, but in general, they go something like this:

- Wire Selection

- Wire Straightening

- Application of Force

Next, manufacturers exert force, whether by machine or hand, to reshape the wire.

- Finishing and Secondary Processes

To ensure the wire product is flawless and free from imperfections such as sharp edges or burrs, manufacturers apply finishing processes to complete the wireforming. These processes include cutting, coining, heading, forming, stamping, coating, and painting.

During wire straightening, manufacturers eliminate stress-induced distortions that have accumulated in the wire. The simplest method for straightening wire is through machine rolling. Alternatively, they can opt for a rotary arbor. Straightening is crucial because, without it, the wire is more prone to breaking and overall instability.

Wire Form Design

When creating a wire form design, manufacturers must take into account various factors. These include application requirements such as chemical properties, mechanical properties, the necessary tolerance value, and the required volume. Following these guidelines, manufacturers can select the appropriate wireform configuration, material, and process. They offer extensive customization options for your wire forms, including the application of powder coatings, nickel plating, or paint, as well as anodizing. Additionally, they can tailor the wire forms with custom diameters, shapes, and dimensions to meet specific needs.

Two critical elements of wireform design are the ends and interior geometries. Typical ends encompass machine cut, chamfered, chisel point, turned, and ball ends. Meanwhile, the interior geometries often feature winging, pierced swaging, custom-shaped holes, grooves, and cold headings.

Machine Cut End

A machine-cut end features a precisely straight edge, created by a die that operates like a guillotine knife. These ends possess minuscule burrs, measuring about 0.13mm, invisible to the naked eye. These burrs are typically so minor that they don’t require removal for the wireform to be deemed complete.

Chamfered End

A chamfered end is one that has been smoothed and subtly shaped by grinding, often with the precision of a lathe. Manufacturers produce these ends to ensure no rough edges remain, making them ideal for applications where even the slightest burr is unacceptable.

Chisel Point and Turn End

A chisel point and turned ends are less precise finishes, crafted with a punching die that smooths out any rough edges.

Ball End

Ball ends are impeccably smooth, free from any edges. They are crafted to perfection using a lathe.

Winding

The winding shape, often referred to as a swaging, resembles a wing. To create it, manufacturers use a die to press down into the wire, carving out the shape by removing metal.

Pierced Swaging

A pierced swaging resembles a winding but stands out with a central hole that adds a unique twist.

Custom Shaped Hole

This shape resembles a pierced swaging, with the distinctive twist of a customized center hole.

Groove

Manufacturers craft grooves using a lathe, with wire grooves frequently serving to secure a retaining ring in place.

Cold Heading

Finally, cold heading is a process where manufacturers transform a wire into a desired shape by forcefully compressing it. Using a pair of gripping dies, the first die firmly secures the wire while the second die strikes it with precision. This technique can produce various head styles, including button heads, collar heads, and carriage heads.

Wire Forming Machinery Used

Wire forming processes utilize a variety of specialized machines. Among the most commonly employed are hydraulic systems, fourslide machines, CNC wire bending machines, and manual levers.

Hydraulic System

Hydraulic wire forming systems comprise a die equipped with a hopper and a hydraulic press. Prior to entering this system, the wire undergoes a straightening process. In this machine, the wire is not only aligned but also relieved of stress, ensuring uniform properties. Following this initial step, the wire is fed into the die, where it is shaped by the press. Occasionally, this task is performed by pick-and-place robots instead of human operators.

Fourslide Machine

A fourslide machine operates by simultaneously stamping wire on a single workpiece from four different directions. This unique approach enables it to function faster than traditional hydraulic presses. Remarkably, with a fourslide machine, a manufacturer can produce up to 3,500 simple stampings per hour. To further enhance the machine’s versatility, manufacturers can utilize multi-purpose dies.

CNC Wire Bending Machine

CNC wire bending machines offer an advanced method for wire forming, leveraging computer numerically controlled (CNC) technology to craft intricate and precise 2D and 3D shapes. CNC wire bending machines are capable of completing a typical project in under an hour, making them the go-to option for custom wire forming due to their efficiency and accuracy.

Advantages and Disadvantages of CNC Wire Bending Machines

Wire bending is an art of shaping and molding wire by applying force to alter its form and contour. Specialized machines deftly create intricate 2D or 3D designs, swiftly bending wires into precise configurations like zigzags, squares, circles, bends, and hooks. These meticulously crafted wire forms find applications across diverse industries, serving as essential components in medical devices, automotive coils and springs, protective sports gear, display racks, construction fences, and beyond. To keep pace with rising demands for custom wire shapes, manufacturers rely on Computer Numerical Control (CNC) wire bending machines for their production needs.

CNC wire bending machines are a significant asset in industrial production. To explore their benefits and drawbacks, continue reading below.

CNC Wire Bending Machine Advantages

- Fast Production

The CNC machines’ bending process is automated based on a pre-programmed design, enabling peak production speeds and high-volume output. Their automated nature also reduces tooling time compared to manual wire bending machines, helping manufacturers meet tight deadlines efficiently.

- High Degree of Precision

Products formed by a CNC wire bending machine boast superior precision compared to those made with manual bending machines. This precision stems from the digital setting of designs, configurations, and dimensions through advanced computer-aided software, enabling consistent and repeatable operations. This high level of accuracy is crucial in industries where component performance can be a matter of life and death, such as in the medical field, aerospace, and military defense.

- Reduced Costs

The meticulous precision of a CNC wire bending machine drastically minimizes scrap metal production. This efficiency translates to significant cost savings for manufacturers, particularly when handling costly materials. Enhanced production speed, pinpoint accuracy, and reduced waste collectively elevate the overall efficiency of each project.

- Exceptionally Versatile

Unlike manual bending machines, CNC wire bending machines excel with their two-dimensional and three-dimensional bending capabilities. With the aid of computer software, manufacturers can tailor products precisely to their customers’ specifications. Furthermore, the cutting-edge technology in modern CNC wire bending machines enables the creation of more intricate designs.

- Less Labor

Despite requiring skilled machinists to operate, CNC wire bending machines do not necessitate a large team. Typically, one trained operator can oversee several CNC machines simultaneously. Once programmed, these machines can work independently, needing only occasional tool changes. This capability allows manufacturers to significantly reduce labor costs.

Manual Lever

Manual lever wire forming is the most ancient technique in wireform fabrication. In this process, manufacturers use a handheld lever and spindle to meticulously bend the wire around and beyond an anvil. This method, however, is not suitable for large-scale productions and often results in inconsistent outcomes.

Variations and Similar Processes

To produce the diverse array of wire forms, various wire forming processes are utilized, with the most common being coil making, roll forming, metal stamping, welding, and weaving.

Coil Making

Coil wire making, often known as coil spring making or coil winding, involves intricately wrapping wires around metal mandrels, creating precisely formed coils.

Roll Forming

Roll forming is a versatile and widely applicable technique used to create flat, round, and variously shaped wire parts. This continuous process involves using rollers and die punches to meticulously shape the wire into its desired form.

Metal Stamping

Another significant wire forming technique is metal stamping, where wire is meticulously crafted into various shapes using a stamping press. There are several methods of metal stamping employed for wire forms, such as fourslide stamping and deep drawn stamping. Fourslide stamping utilizes a press equipped with four horizontal forming slides, enabling the creation of multiple shapes in different directions. Conversely, deep drawing focuses on the depth of the form rather than the quantity of forms. This method permits a greater depth in wire formation than any other technique.

Welding

Ultimately, welding is a procedure driven by chemical reactions. This term also encompasses a variety of spot or seam welding techniques, such as electric resistance welding (ERW), metal inert gas (MIG) welding, or tungsten inert gas (TIG) welding. ERW specifically employs an electric current combined with mechanical pressure to fuse wire together. As varieties of ERW, both MIG and TIG welding employ inert gasses to minimize contamination. While TIG welding offers the highest precision, it demands greater complexity, necessitating a highly skilled operator and extended production times. Consequently, MIG welding is frequently preferred. Additionally, weaving techniques may be employed to fabricate wire forms such as screens, grids, or guards.

Weaving

Another, less commonly used wire forming technique is weaving, which is employed to create items such as screens, grids, and guards.

Wire Forming Benefits

Wire forming brings a multitude of advantages, making it a favored manufacturing technique across many industries. First and foremost, its versatility stands out, enabling the creation of intricate shapes and designs. Whether it’s bending, twisting, coiling, or shaping, wire forming can adapt to numerous configurations, catering to a diverse array of applications. Furthermore, wire forming is renowned for producing components with exceptional strength and durability. The unique characteristics of wire, along with the ability to select the right material and thickness, lead to the creation of durable products capable of bearing heavy loads and enduring tough environments. An added benefit of wire forming is its economical nature. Wire is generally inexpensive and easily accessible, making it a budget-friendly option for numerous uses. Moreover, wire forming offers lightweight solutions, a critical factor in industries like aerospace and automotive, where reducing weight is key to enhancing fuel efficiency and performance. Ultimately, wire forming provides a pathway for customization and swift prototyping. The capability to craft unique wire shapes and configurations empowers manufacturers to swiftly produce bespoke solutions tailored to precise needs. This adaptability accelerates prototyping and fosters the creation of innovative designs. In essence, wire forming offers an array of benefits—versatility, strength, cost-effectiveness, lightweight construction, and customization—making it a highly advantageous process across a wide range of industries.

Things to Consider When Selecting a Wireform Manufacturer

For the highest quality wire form, we recommend partnering with an experienced wireform manufacturer. By doing so, you’ll receive expert advice and top-notch services. To aid in your search, we’ve compiled a comprehensive list of our most trusted custom wire form suppliers. Spend a few moments reviewing what each has to offer. Once you’ve narrowed down your choices, reach out to three or four manufacturers that pique your interest and discuss your specifications. If your project is complex, don’t hesitate to request prototype work. This will ensure the manufacturer fully understands your application, enabling you to choose a partner capable of meeting your exact requirements. Then, make your selection and get started.

Check out our Metal Stampings website

Wire Forms – Acme Wire Products Company, Incorporated

Wire Forms – Acme Wire Products Company, Incorporated

Cold Headed Parts

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services