Rod bending tools range from small, handheld devices, to automated machines. Bending tools are made to adjust the bending angle by reference, stroke measure or angle measure. There are several classification of bending tools. Read More…

Acme Wire Products provides close tolerance wire fabrications using steel and stainless steel. Customized applications include a wide range of wire forms for many different applications. Acme works with wire from .050 to .500 diameter.

CUSTOM "Spring & Wire Form Specialists" - Ace Wire Spring & Form incorporates the latest CNC equipment technology to manufacture compression, extension, torsion springs, complex wire forms, and spring assemblies. We offer consistent quality, lower costs, on-time deliveries, and Design Engineering Assistance. Range from prototypes to long production runs - Family owned & operated since ...

Apex Spring & Stamping is a certified minority owned company that manufacturers springs, stampings, wire forms, clips, and fasteners. Our core industries include automotive, office furniture, medical, recreational, consumer goods, and appliances. We also specialize in value added assembly and prototyping. Our engineering team will ensure your part is both functional and cost-effective. IATF 16949 ...

Smith & Richardson, Inc. is a leading provider of precision machining services, offering an extensive range of capabilities including CNC Swiss machining, Wire EDM machining, vertical and horizontal machining, CNC milling, CNC turning, assembly services, and more. With a strong commitment to quality and innovation, we serve the medical, aerospace, casting, and automotive industries, delivering...

At Elyria Spring & Specialty, LLC, we are proud to offer a wide array of high-quality wire forms and comprehensive solutions tailored to meet the diverse needs of our valued customers. With a rich history of expertise and a steadfast commitment to excellence, we have established ourselves as a trusted leader in the wire forming industry. Our product portfolio encompasses a diverse range of wire...

Here at Anderson Quality Spring Manufacturing, Inc., we take great pride in our position as a leading provider of wire forms, offering a comprehensive range of products, services, and capabilities to meet the diverse needs of our valued clientele. With our unwavering commitment to excellence and extensive expertise in wire forming technology, we stand ready to deliver innovative solutions that...

At New England Spring, we pride ourselves on being a premier provider of high-quality wire forms and comprehensive solutions tailored to meet the diverse needs of our valued customers. With decades of experience and a steadfast commitment to excellence, we have established ourselves as a trusted leader in the wire forming industry. Our product portfolio encompasses a wide range of wire forms,...

More Rod Bending Manufacturers

Established bending tool types are: Standard Bends, U-Bending, Offset Bending, Edgewise Bending and Torsion Bending. In their own categories, respectively, are CNC Bending machines and Universal Bending Machines-Modular Construction. Classifications are determined by the kind of bends they generate.

Standard Bending tools produce bends without extraordinary geometry. The distance between a bend and material end is rather high, assuming an adequate bearing area. The same is also true from one bend to the next.

U-Bending tools make, as the name implies, “U”-shaped rods, like piping for below sinks. When the required bends are more tight and narrow than the tool can handle, a U-Bend tool is swapped out for a bending mandrel, which has narrow geometry. Offset bending tools are used to assemble two bends with a small distance between each other in one step. Edgewise Bending tools are used when a bending axis is placed parallel to the tight side of the workpiece.

This type of tool may come equipped with electronic angular measurement component, to ensure a high bending accuracy. Torsion Bending tools are able to rotate the workpiece on a longitudinal axis.

A consumer can alternatively achieve a similar end by using complex assembly groups with standard bends. CNC wire bending machines are a fairly recent development, and they have been designed for high flexibility and a quick set-up. They are able to economically bend both single pieces and small batches with the same level of precision and efficiency as series-produced parts. The final category of Rod Bending tool is the Universal Bending Machine-Modular Construction.

This type of tool consists of a basic machine that is adjustable with little effort and can therefore be applied to a number of bends. The exchange of tools, supported by a simple plug-in system, is quick and easy.

The basic machine is comprised of a CNC-operated side stop, a work bench and software for programming and operating. Because of its modular construction, this machine offers an affordable gateway into bending technology.

After the initial investment, a machine can be customized and extended without any conversion. In other words, the basic machine provides a bending stroke, while the kind of bending is determined by the accompanying tool.

Bending tools are great for a number of industries and markets. Types of construction, among other, to which the Universal Bending Machine lends itself, are metal construction, steel construction, metalwork, machine construction and utility vehicle construction.

Cold Headed Parts

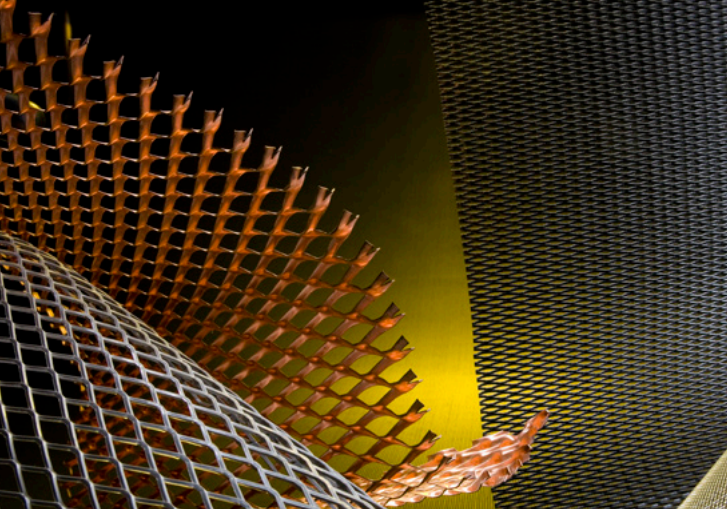

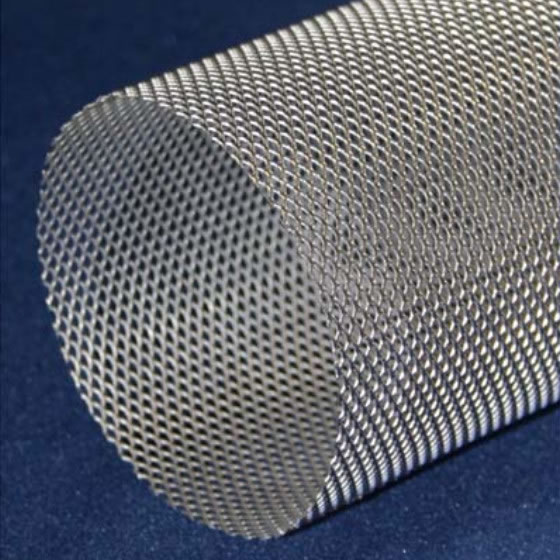

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services