Wire Parts

Wire parts, commonly referred to as wire forms, are formed from wire that has been manipulated in some fashion into a specific shape or design. After the wire has been formed from raw materials, it is then further fabricated to create various wire parts. Read More…

Acme Wire Products provides close tolerance wire fabrications using steel and stainless steel. Customized applications include a wide range of wire forms for many different applications. Acme works with wire from .050 to .500 diameter.

CUSTOM "Spring & Wire Form Specialists" - Ace Wire Spring & Form incorporates the latest CNC equipment technology to manufacture compression, extension, torsion springs, complex wire forms, and spring assemblies. We offer consistent quality, lower costs, on-time deliveries, and Design Engineering Assistance. Range from prototypes to long production runs - Family owned & operated since ...

Apex Spring & Stamping is a certified minority owned company that manufacturers springs, stampings, wire forms, clips, and fasteners. Our core industries include automotive, office furniture, medical, recreational, consumer goods, and appliances. We also specialize in value added assembly and prototyping. Our engineering team will ensure your part is both functional and cost-effective. IATF 16949 ...

Smith & Richardson, Inc. is a leading provider of precision machining services, offering an extensive range of capabilities including CNC Swiss machining, Wire EDM machining, vertical and horizontal machining, CNC milling, CNC turning, assembly services, and more. With a strong commitment to quality and innovation, we serve the medical, aerospace, casting, and automotive industries, delivering...

At Elyria Spring & Specialty, LLC, we are proud to offer a wide array of high-quality wire forms and comprehensive solutions tailored to meet the diverse needs of our valued customers. With a rich history of expertise and a steadfast commitment to excellence, we have established ourselves as a trusted leader in the wire forming industry. Our product portfolio encompasses a diverse range of wire...

Here at Anderson Quality Spring Manufacturing, Inc., we take great pride in our position as a leading provider of wire forms, offering a comprehensive range of products, services, and capabilities to meet the diverse needs of our valued clientele. With our unwavering commitment to excellence and extensive expertise in wire forming technology, we stand ready to deliver innovative solutions that...

At New England Spring, we pride ourselves on being a premier provider of high-quality wire forms and comprehensive solutions tailored to meet the diverse needs of our valued customers. With decades of experience and a steadfast commitment to excellence, we have established ourselves as a trusted leader in the wire forming industry. Our product portfolio encompasses a wide range of wire forms,...

More Wire Part Manufacturers

Useful in a broad range of applications, wire parts are beneficial for many industries because of their durability and conductivity as well as their versatility. Some of the many applications of wire parts include: wire grids, racks, POP displays and shelving, which are commonly used in retail, commercial and residential industries; wire light guards, DIN rails, wireways and cable trays, which are often utilized in the electronics industry; wire brackets, busbars and gratings that are used in construction and architectural industries; and wire motor mounts, machine guards, wire baskets and screens, for the industrial manufacturing industry.

Also useful in the automotive and aerospace industries, additional wire parts include grilles, coils, clips, hooks, rings, fasteners, hangers and springs. In addition to the many shapes and designs, wire parts can be made with a wide range of materials, chosen for their suitability in certain applications. Commonly made from steel or stainless steel, both metals suitable for corrosive environment, wire parts can also be made from plastics, aluminum, brass, copper and various metal alloys.

In accordance with the vast range of wire parts, there are numerous wire forming processes used to create them. Some of the more common wire forming processes include metal stamping, roll forming, CNC wire forming, weaving and welding. Metal stamping processes involve using a stamping press to form flat metal wire into precisely shaped metal parts. Popular metal stamping processes for wire forming include deep drawing, short run and fourslide. Roll forming is another major wire forming process, able to create flat, round and shaped wire parts.

A continuous process, roll forming uses calenders and die punches to shape metal wire into various forms. CNC wire forming processes utilize computer controls in order to ensure a higher level of precision than with other processes; thus, CNC wire forming can include other wire forming processes such as bending or welding but are altered due to the addition of CNC capabilities.

Weaving processes are simply methods of interlacing various threads into a pattern similar to a cloth, or on a larger scale with gaps such as a grid. Lastly, wire welding can refer to various processes, the most common of which are MIG welding or TIG welding. TIG welding is the most accurate type of wire welding, however it is much more complex and requires a very skilled operator as well as longer production times, so MIG welding is often used instead.

Cold Headed Parts

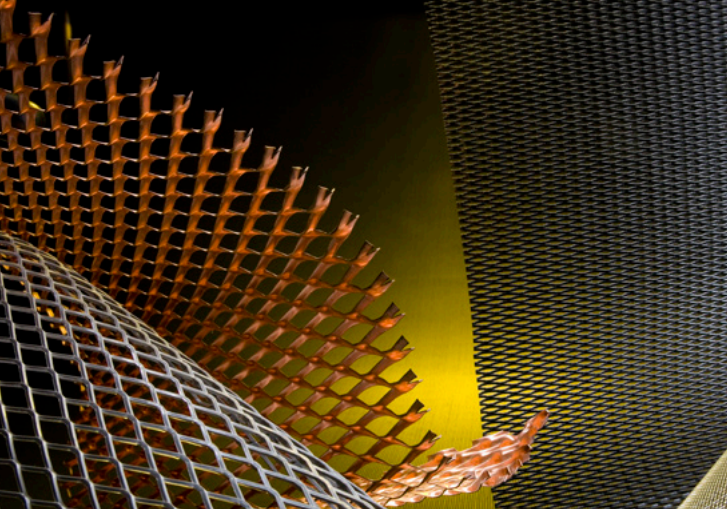

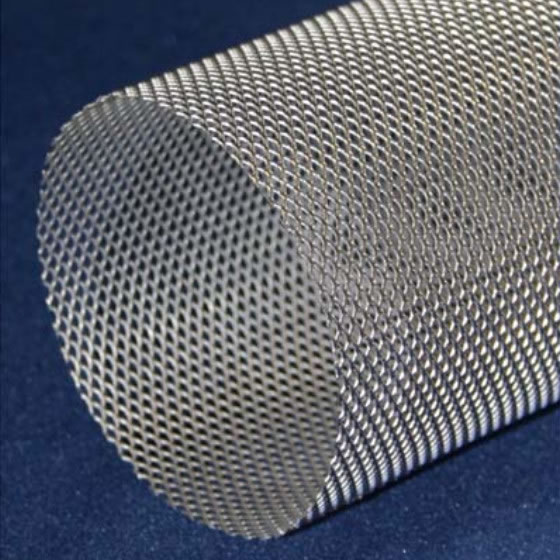

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services