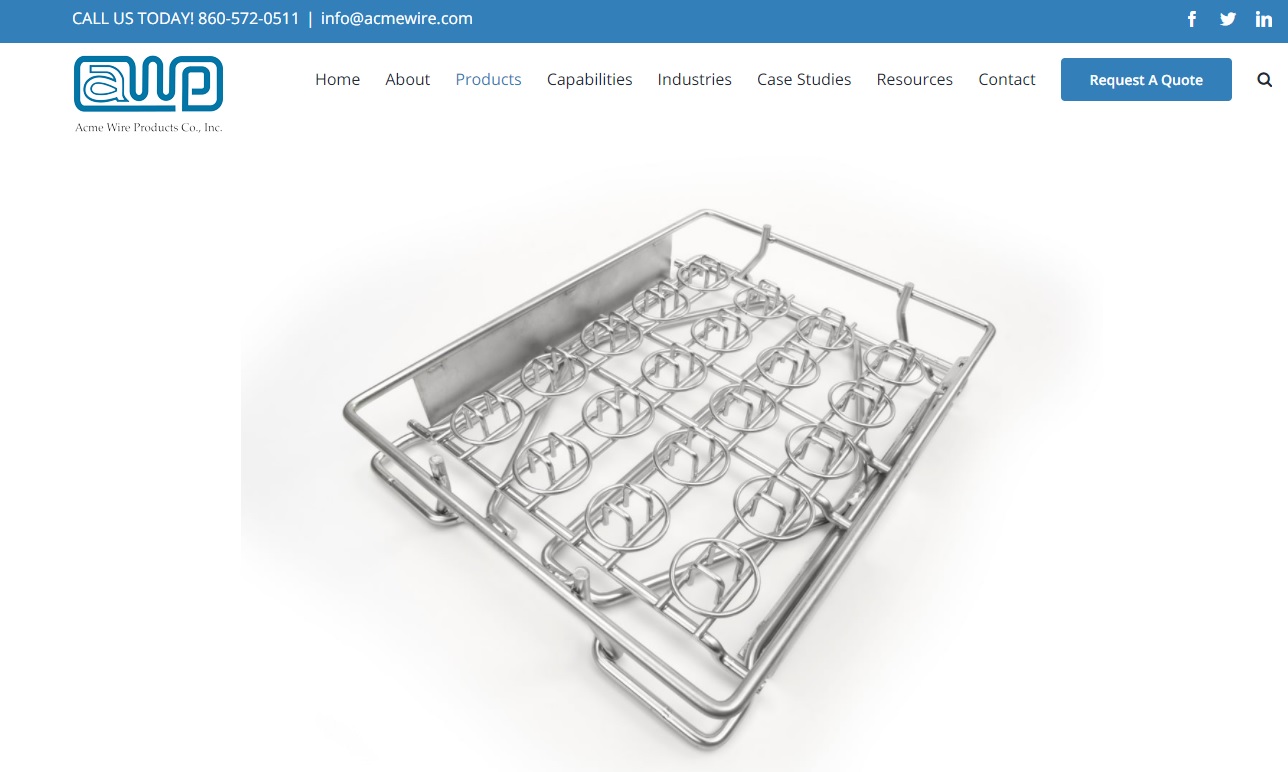

A wire basket is an organizational tool constructed from welded or woven wires forming a basket shape. A wire basket may be used just as a plastic basket is used for storing or organizing things around the house. Wire baskets are also found in grocery stores replacing the plastic shopping basket types. Read More…

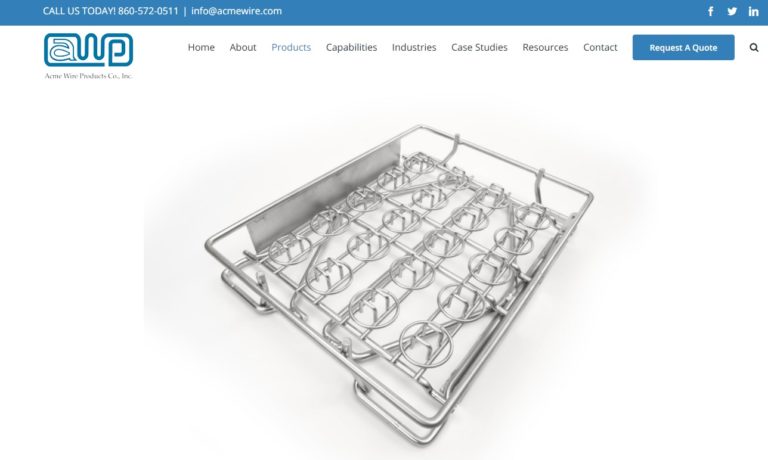

Acme Wire Products provides close tolerance wire fabrications using steel and stainless steel. Customized applications include a wide range of wire forms for many different applications. Acme works with wire from .050 to .500 diameter.

CUSTOM "Spring & Wire Form Specialists" - Ace Wire Spring & Form incorporates the latest CNC equipment technology to manufacture compression, extension, torsion springs, complex wire forms, and spring assemblies. We offer consistent quality, lower costs, on-time deliveries, and Design Engineering Assistance. Range from prototypes to long production runs - Family owned & operated since ...

Apex Spring & Stamping is a certified minority owned company that manufacturers springs, stampings, wire forms, clips, and fasteners. Our core industries include automotive, office furniture, medical, recreational, consumer goods, and appliances. We also specialize in value added assembly and prototyping. Our engineering team will ensure your part is both functional and cost-effective. IATF 16949 ...

Smith & Richardson, Inc. is a leading provider of precision machining services, offering an extensive range of capabilities including CNC Swiss machining, Wire EDM machining, vertical and horizontal machining, CNC milling, CNC turning, assembly services, and more. With a strong commitment to quality and innovation, we serve the medical, aerospace, casting, and automotive industries, delivering...

At Elyria Spring & Specialty, LLC, we are proud to offer a wide array of high-quality wire forms and comprehensive solutions tailored to meet the diverse needs of our valued customers. With a rich history of expertise and a steadfast commitment to excellence, we have established ourselves as a trusted leader in the wire forming industry. Our product portfolio encompasses a diverse range of wire...

Here at Anderson Quality Spring Manufacturing, Inc., we take great pride in our position as a leading provider of wire forms, offering a comprehensive range of products, services, and capabilities to meet the diverse needs of our valued clientele. With our unwavering commitment to excellence and extensive expertise in wire forming technology, we stand ready to deliver innovative solutions that...

At New England Spring, we pride ourselves on being a premier provider of high-quality wire forms and comprehensive solutions tailored to meet the diverse needs of our valued customers. With decades of experience and a steadfast commitment to excellence, we have established ourselves as a trusted leader in the wire forming industry. Our product portfolio encompasses a wide range of wire forms,...

More Wire Basket Manufacturers

They may be used for storing items when they’re hanging from walls in garages. Wire baskets allow people to see the things stored inside at a glimpse. Wire baskets are usually open, that's why they’re ideal for items which are used frequently, such as sports equipment and cleaning tools.

Considerations When Manufacturing Wire Baskets

There are several factors to consider when choosing wire baskets such as below:

Manufacturing Contents

Damaging chemicals are common constituents in many parts of finishing processes. The materials used in wire baskets should be better able to withstand frequent and prolonged exposure to all types of chemicals used in finishing parts.

Size, Weight and Shape of Items

Some of the factors which come prior to buying wire baskets are weight and the physical sizes of the items which the basket will carry. The basket must be strong enough so that it can fit and hold the parts.

Surface Condition Requirements for Items

The condition or appearance of the surface for held items must be considered as well as the rigidity of the surface of the held items. Parts which require no scratches or abrasions should be held in a different manner than items where small surface scratching or abrasion might not matter greatly.

Storage Environment

This is a commonly overlooked factor. A washing basket may be ruined by continually exposing it to chemicals or air contaminants. Knowing the contents of air in the factory or storage area where the wire basket will be used may help optimize the period of use of the basket.

Processing Temperature and Exposure Time

Several specialized coats and alloys react in different ways when they are exposed to high temperatures. Many steel alloys may lose tensile strength at extreme temperatures, or become brittle in low temperatures. Several coatings may be damaged by extended exposure to extreme temperatures.

Types of Wire Baskets

There are several types of wire baskets, serving different uses. Below are some of the common types of wire baskets:

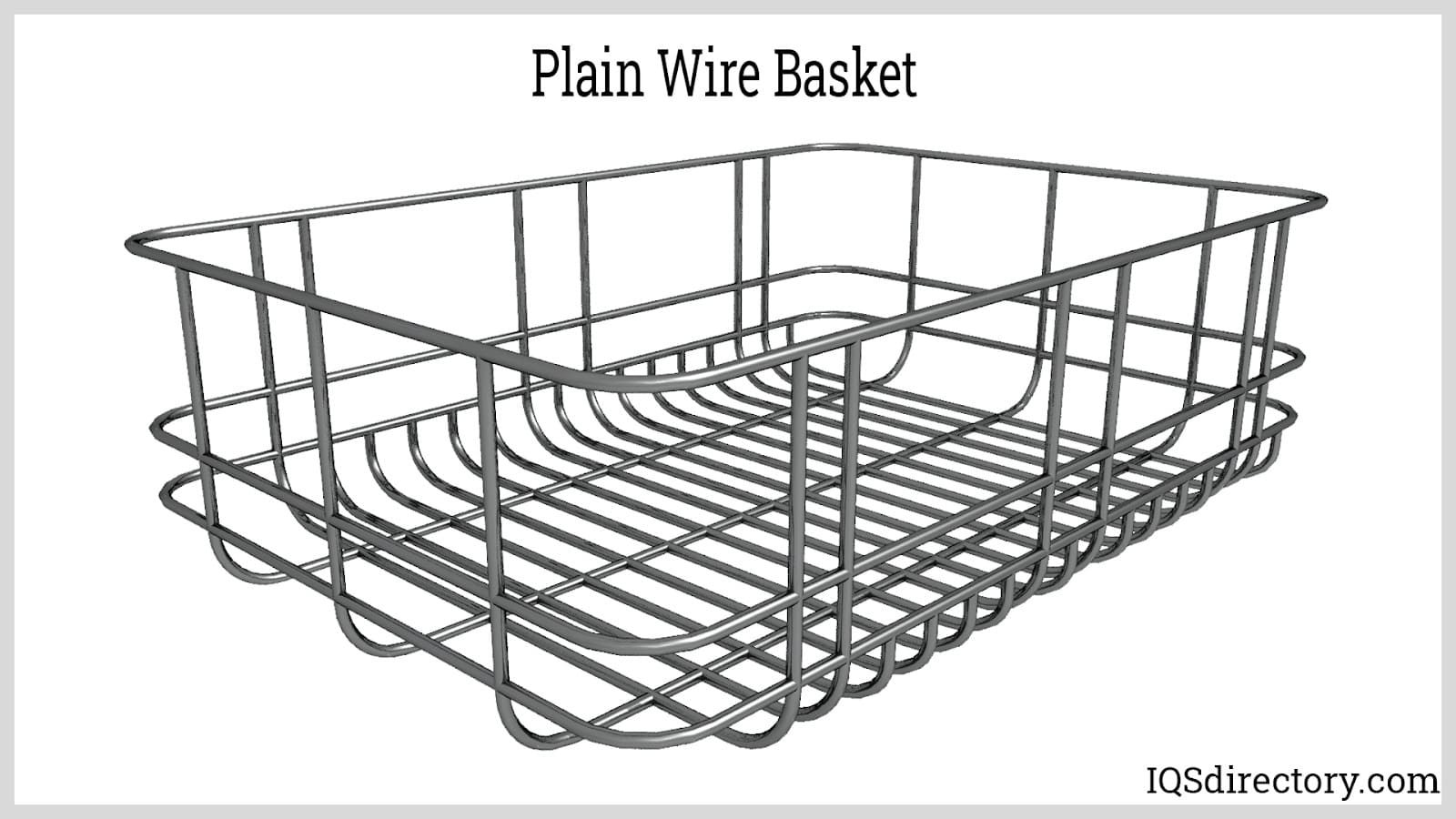

Plain Wire Basket

Plain wire baskets are usually used in kitchens because they are simple in handling and use. They are made from simple steel wires woven to form a rigid rectangular-shaped basket. They are available in a number of shapes and sizes.

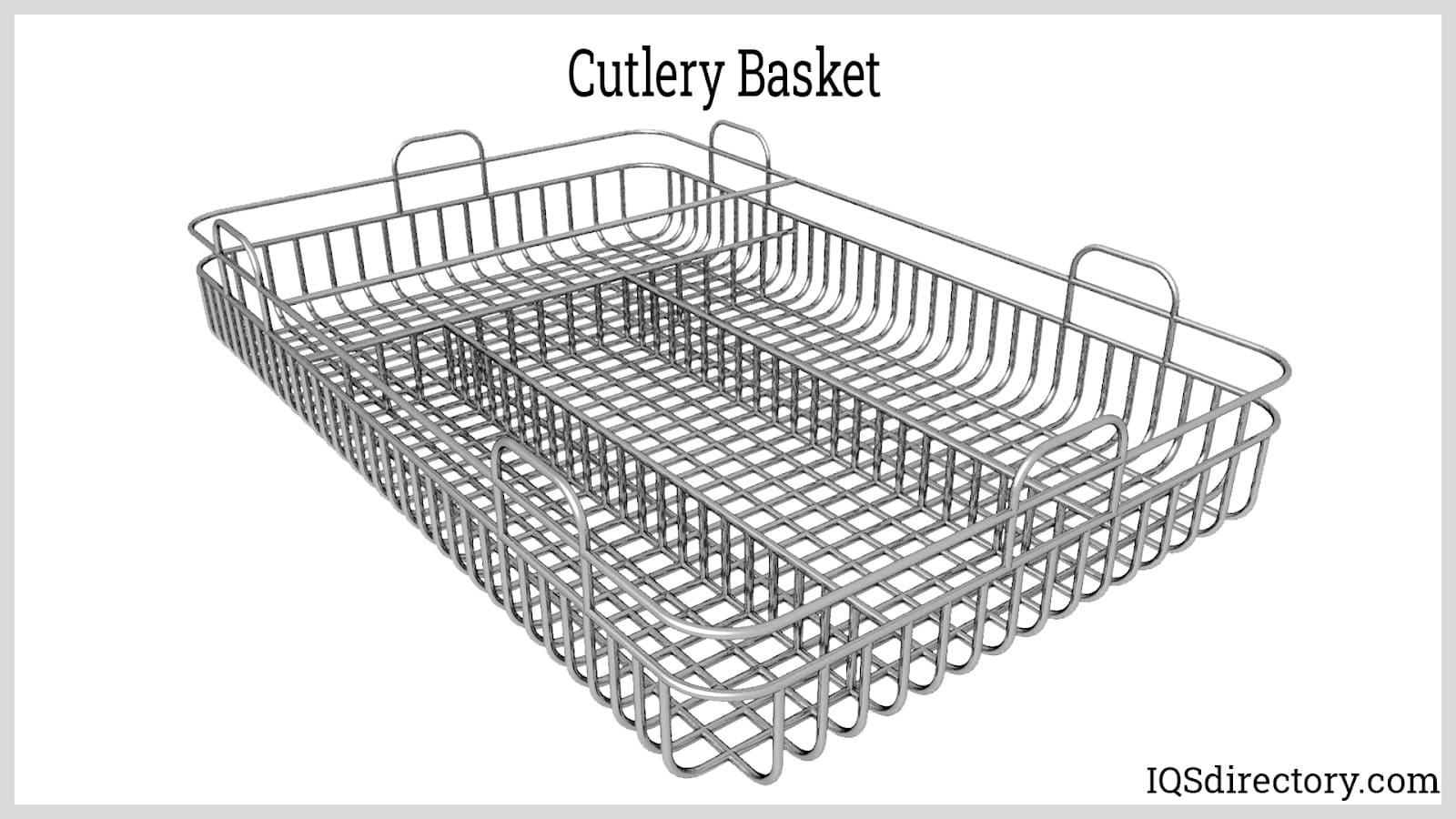

Cutlery Basket

This wire basket is important in storing small and thin utensils. They are made with thick perforated sheets at the base. The baskets are made portable by having molded spaces which can handle various types of kitchen items in separated compartments. They are handy because they often feature various compartment sizes and could help save money by cutting down on required storage space.

Bin Basket

A bin basket is essential in keeping the household clean. It can be kept under or behind furniture. Waste items and unwanted items are thrown into these baskets and emptied later. They keep the household hygienic and prevent buildup of nasty odors. They are made of gauze metal sheets with small perforated metal or plastic plates at the base. Bin baskets are quite expensive compared to other types.

Wire Shopping Basket

They are usually used in supermarkets by customers buying several products which cannot be carried easily, such as frozen or fragile products. Wire shopping baskets are made from a collection of mashed, woven steel wire. They can withstand heavy loads and are quite light when empty.

Wire Storage Basket

These are particularly useful for organizing small things in one place and eliminating clutter. They’re made from stainless steel with a special vinyl coat or chrome wire plating. This type of basket’s dense mesh emphasizes its strength and holding capacity. It can hold garage tools together or other equipment regardless of weight, size or shape.

Applications of Wire Baskets

Wire baskets are adaptable. They can be put on shelves, hung on the wall, or displayed on the desk. Using wire baskets for storing items in the house is a good way to help clear clutter and keep the place clean. The surface of wire baskets make them a good addition to the complete look and feel in a home. They are practical organizing tools and decorative pieces rolled into one.

Choosing the Proper Wire Basket Manufacturer

To make sure you have the most productive outcome when purchasing wire baskets from a wire basket manufacturer, it is important to compare at least 4 companies using our list of wire basket manufacturers. Each wire basket manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each wire basket business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple wire basket manufacturers with the same message.

Cold Headed Parts

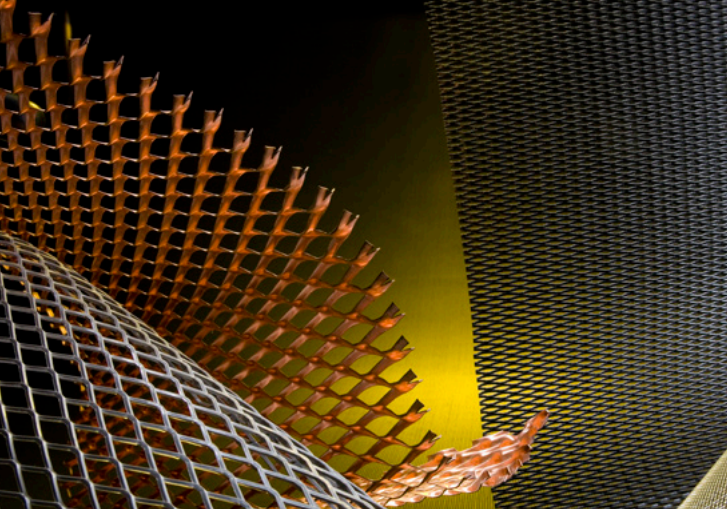

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

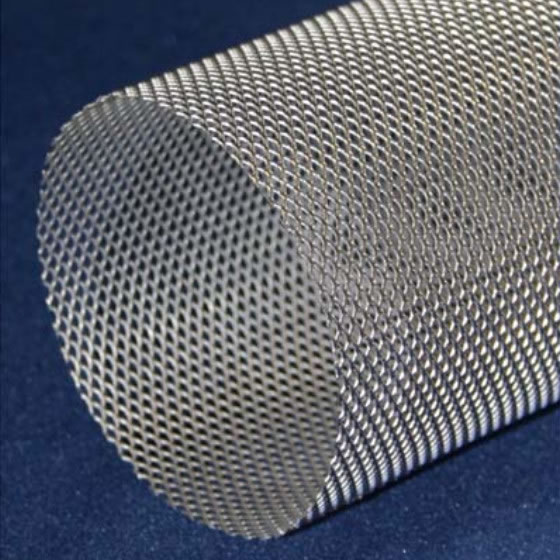

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services