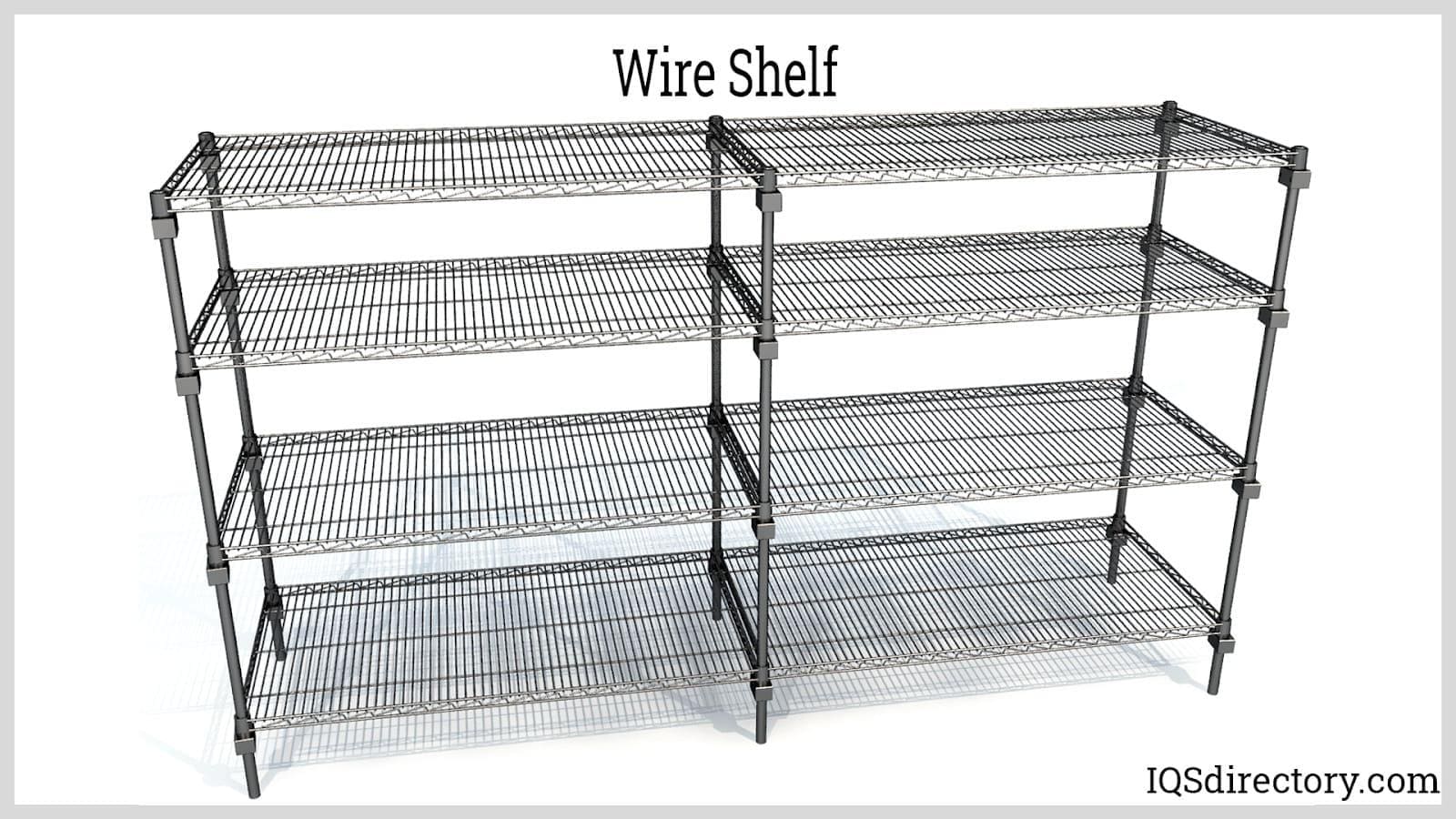

Wire Shelves

Industrial shelving, called wire storage shelves, is often made of metal wire mesh. This shelving is used in various industrial and commercial environments, including warehouses, commercial kitchens, and retail establishments. Various metals may be used to create shelving depending on the metals’ specific strengths and the specific application of the shelves. Read More…

Acme Wire Products provides close tolerance wire fabrications using steel and stainless steel. Customized applications include a wide range of wire forms for many different applications. Acme works with wire from .050 to .500 diameter.

CUSTOM "Spring & Wire Form Specialists" - Ace Wire Spring & Form incorporates the latest CNC equipment technology to manufacture compression, extension, torsion springs, complex wire forms, and spring assemblies. We offer consistent quality, lower costs, on-time deliveries, and Design Engineering Assistance. Range from prototypes to long production runs - Family owned & operated since ...

Apex Spring & Stamping is a certified minority owned company that manufacturers springs, stampings, wire forms, clips, and fasteners. Our core industries include automotive, office furniture, medical, recreational, consumer goods, and appliances. We also specialize in value added assembly and prototyping. Our engineering team will ensure your part is both functional and cost-effective. IATF 16949 ...

Smith & Richardson, Inc. is a leading provider of precision machining services, offering an extensive range of capabilities including CNC Swiss machining, Wire EDM machining, vertical and horizontal machining, CNC milling, CNC turning, assembly services, and more. With a strong commitment to quality and innovation, we serve the medical, aerospace, casting, and automotive industries, delivering...

At Elyria Spring & Specialty, LLC, we are proud to offer a wide array of high-quality wire forms and comprehensive solutions tailored to meet the diverse needs of our valued customers. With a rich history of expertise and a steadfast commitment to excellence, we have established ourselves as a trusted leader in the wire forming industry. Our product portfolio encompasses a diverse range of wire...

Here at Anderson Quality Spring Manufacturing, Inc., we take great pride in our position as a leading provider of wire forms, offering a comprehensive range of products, services, and capabilities to meet the diverse needs of our valued clientele. With our unwavering commitment to excellence and extensive expertise in wire forming technology, we stand ready to deliver innovative solutions that...

At New England Spring, we pride ourselves on being a premier provider of high-quality wire forms and comprehensive solutions tailored to meet the diverse needs of our valued customers. With decades of experience and a steadfast commitment to excellence, we have established ourselves as a trusted leader in the wire forming industry. Our product portfolio encompasses a wide range of wire forms,...

More Wire Shelve Manufacturers

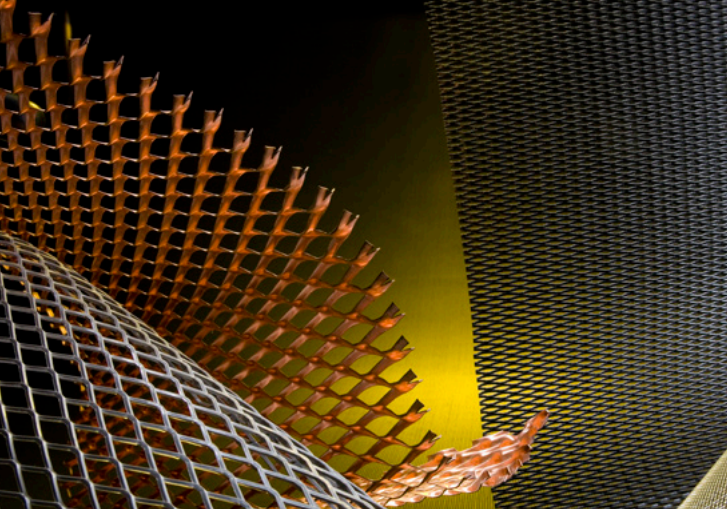

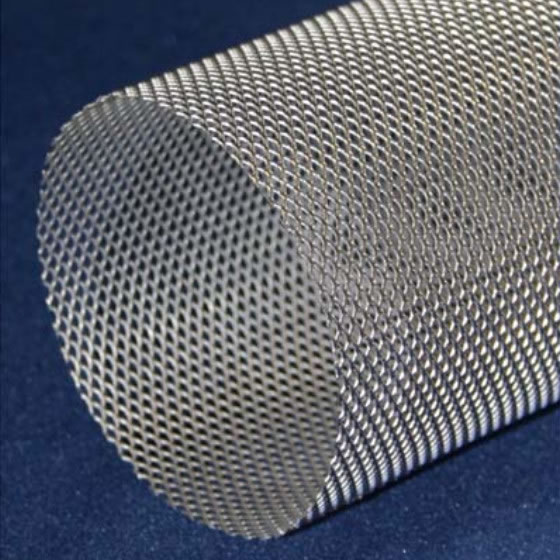

Types of Metals Used in Wire Shelves

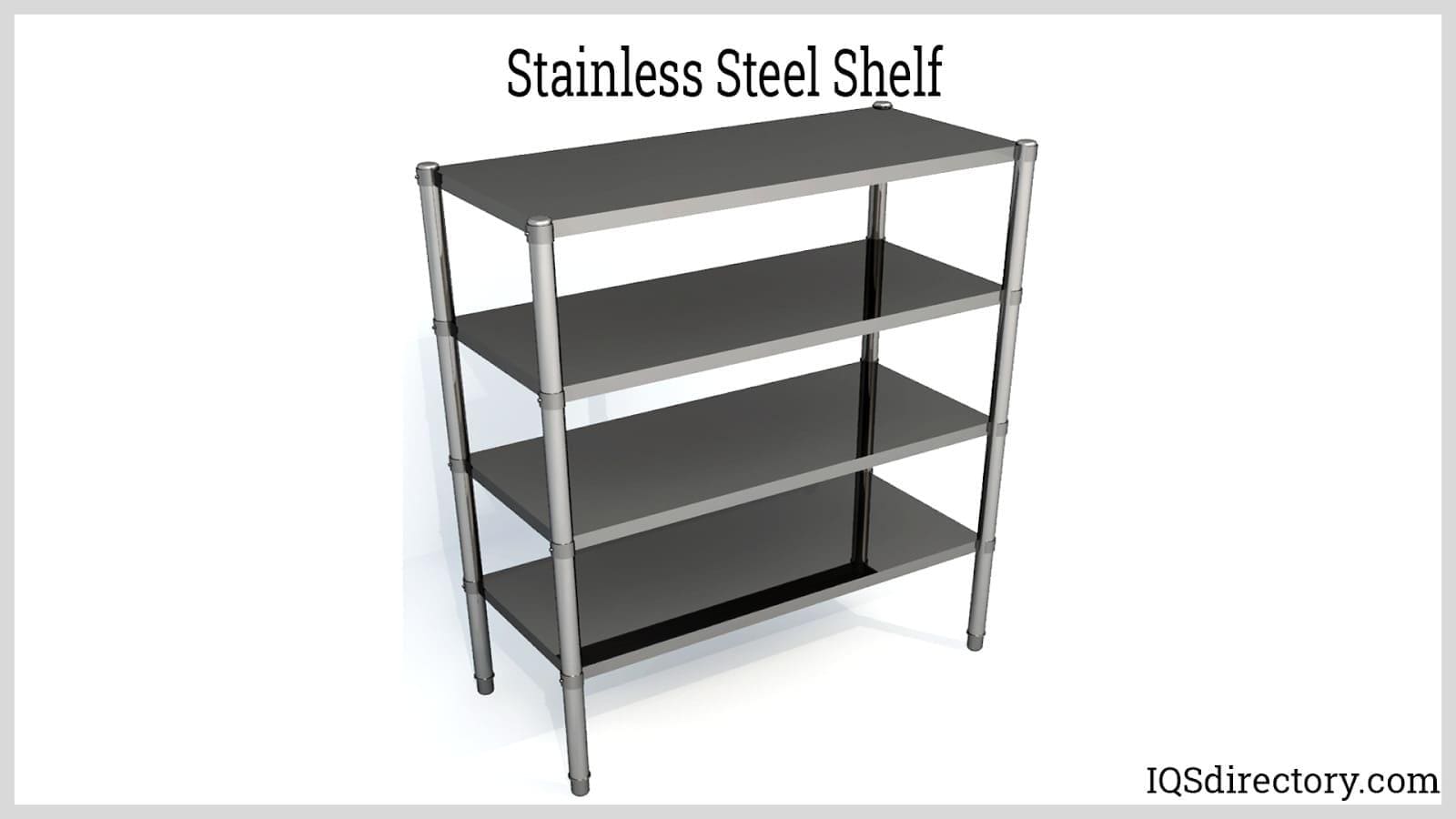

Stainless Steel

Stainless steel shelving is among the most popular types of wire shelving available today. Stainless steel is ideally suited for demanding applications and rough handling because of its uncompromised durability and inherent resistance to rust and corrosion. Weight capacity is the main benefit of stainless-steel wire shelving. Some versions may have a stronger structure to support heavier weights.

These robust types might have shelves reinforced with double rivets, thicker upright columns, or shelves made of heavier steel gauge. Although substantially more expensive, heavy-duty stainless-steel shelves are perfect for high-density storage applications (such as heavy parts, machine elements, tools, etc.).

A stainless-steel wire shelving unit is the best option if the storage requirements involve moist areas or wet products because it won't rust or corrode even after years of use. In addition, stainless steel shelving is the best option for any application requiring rust- and corrosion-proof storage with a high weight capacity, including shelving for wet or dry storage, a walk-in refrigerator, and other uses. Most wire shelving uses stainless steel alloys with an average chromium content of 18%. This material's extraordinary resistance to rust and corrosion is mostly due to the chromium component.

Carbon Steel

Carbon steel is a common substitute for stainless steel in wire shelving systems. Stainless steel and carbon steel are both strong steel alloys, but there are some significant differences. Like stainless steel, which has a high chromium content, a carbon steel alloy, as its name implies, has a high carbon content. Since carbon steel wire shelves have a different level of corrosion and rust resistance than their stainless-steel counterparts due to this difference in alloy content, they might not be appropriate for storage in humid locations.

However, compared to conventional stainless steel, several varieties of carbon steel—particularly high-carbon alloys—are tougher and have higher tensile strengths. The carbon steel variant will typically be stronger than its stainless-steel counterpart, sustaining a higher weight capacity and enduring longer when comparing wire shelves with comparable dimensions.

Due to its propensity to more readily retain visible traces of surface damage, carbon steel shelving may not be as aesthetically appealing as stainless, plated, or coated shelving (e.g., surface wear and tear). However, the shelving units made of this material cost less than those of stainless steel.

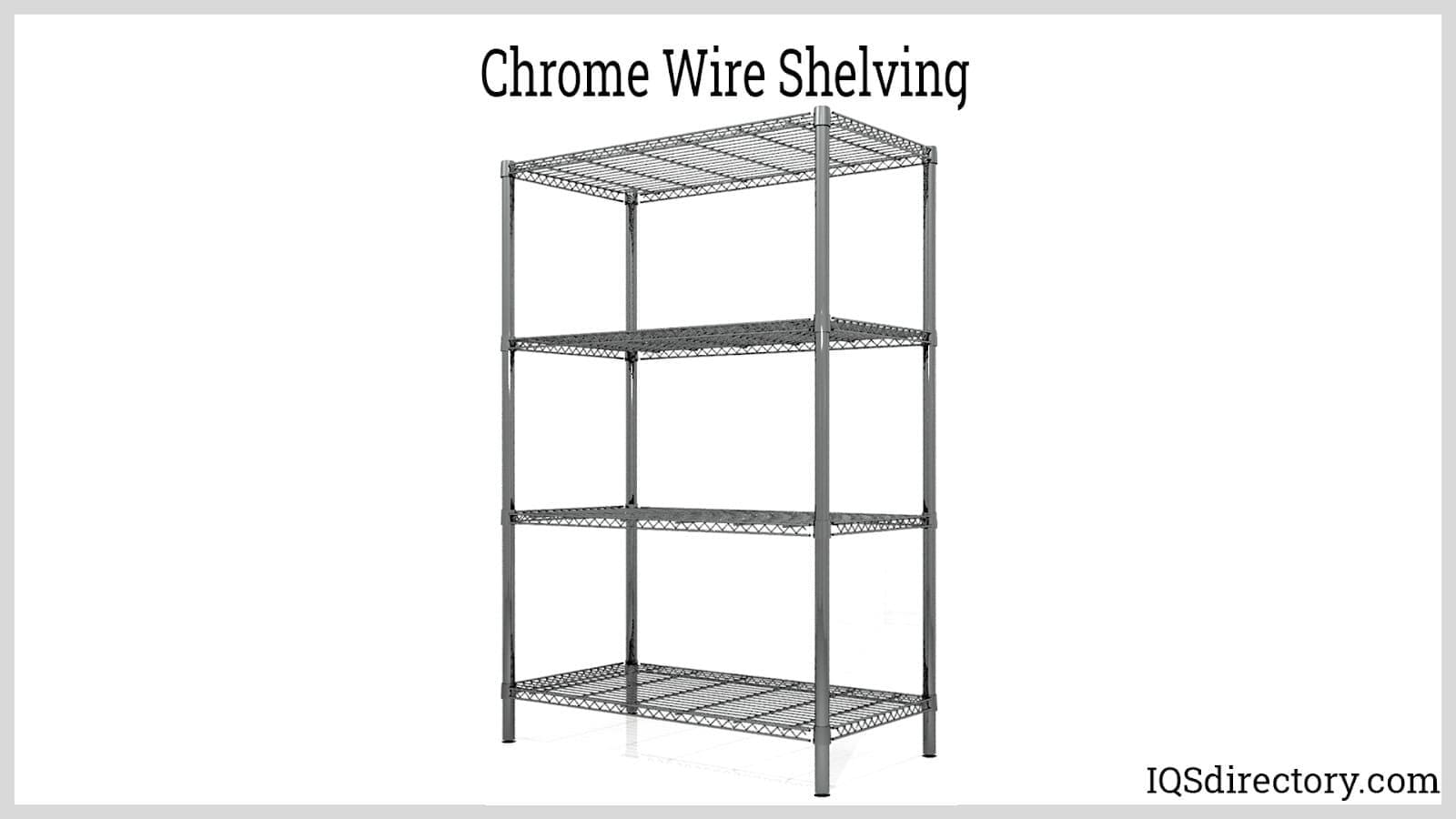

Chrome (Nichrome)-Plated Wire Shelves

Metals electroplated with chromium are referred to as chrome plated. The chrome or nichrome coating improves the shelving unit's corrosion resistance. Because they provide a superb blend of durability and versatility, chrome-plated wire shelving, also known as chrome wire shelves, is among the most well-liked wire shelving systems available. Stainless steel, as previously mentioned, is the most commonly known metal with this protection.

However, other metals may receive this beneficial coating as well. The chrome plating increases the shelving unit's durability and resistance to wear and tear to a lesser extent than its strength or weight capacity. Two less well-known benefits are the great resistance to dust and sanitary certifications of chrome-plated wire shelving. In addition, the wire shelving is made easier to clean by chrome plating, which forms a surface that keeps dirt and debris off its surface.

Zinc-Plated Wire Shelves

Zinc plating fundamentally differs from chrome plating, even if they appear identical at first glance. Zinc-plated wire shelving is created using an electroplating method similar to that used for chrome plating, which involves coating the surface of galvanized steel with a thin layer of zinc chromate. Zinc plating increases the shelving unit's resistance to rust and corrosion, much like chrome plating. The main distinction between zinc and chrome plating is the wire shelving unit's capacity to withstand wear and tear. Although zinc plating is less durable it is less expensive than chrome. The color and finish are fairly similar between both processes.

The Advantages of Wire Shelving

Any storage system can be enhanced or complemented by using wire shelving solutions. Here are a few advantages of wire shelving for storage.

Affordable: In contrast to other storage options, wire shelving is manufactured using inexpensive components and simple assembly techniques. As a result, this shelving is frequently significantly less expensive than other storage choices, making it a great choice for facilities that require additional storage space but are on a tight budget.

Simple to Reconfigure: The simplicity of reconfiguring wire shelving units is one of their main benefits. Typically, wire shelving decks are constructed from metal rods that are fastened together with clips or other hardware. This design makes adding or removing shelves straightforward, and the shelves can be moved to different heights as desired. These characteristics are important in warehouses where it is common to need to store things of various sizes.

Simple to Install: Additionally, installing wire shelving is typically a simple process that only requires little special equipment or expertise. Integrated inventory management is simple to maintain with wire shelving.

Applications of Wire Shelves

Applications of wire storage shelves are found in many sectors of the economy. Some typical uses are listed below:

Manufacturing and Storage of Food and Hospitality Applications: Because of their toughness and resistance to corrosion, wire shelving units are ideal for use in the manufacturing and storage of food and hospitality environments. For instance, wire shelving's smooth, simple-to-clean surface makes it simpler to abide by food safety and quality laws and regulations, such as those provided by the FDA.

Presentation Shelves: The transparent appearance of the porous wire rack construction, which is less imposing than other shelving units, is frequently used as presentation shelves.

Medical Applications: Because they are less likely to accumulate dust, wire shelves are also ideal for the medical applications.

Industrial Applications: In addition, metal wire is frequently the material of choice for shelving in factories and warehouses with possible extensive storage because this openness is more compatible with building and fire safety codes, as the concave surfaces do not obstruct emergency sprinkler systems. The flow of air is also unimpeded. Although water and air can easily pass through a wire shelf, the porous design does not preclude the closure of this type of shelf for improved product security. In addition, wire shelves frequently have protective wire grids or screens that keep inventory contained and safe while maintaining visibility.

Choosing the Right Wire Shelves Manufacturer

To make sure you have the most beneficial outcome when purchasing wire shelves from a wire shelves manufacturer, it is important to compare at least 4 manufacturers using our wire shelves directory. Each wire shelves manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each wire shelves company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple wire shelves companies with the same quote.

Cold Headed Parts

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services