Wire Products

Wire products are created when wire is bent, stamped, or fabricated into various shapes and sizes to produce specific shapes and sizes. These products are used to hold the everyday, small and big things that consumers need. Our world has come to depend heavily on wire products. For example, they are found in retail businesses for wire shelving or for containers used in storage and shipping industries. Wire racks, clips, pins, springs, hooks, rings, shelves and baskets are common in a variety of industries. Meanwhile, wire guards and screens are commonly used as a way of improving workplace safety. Read More…

Acme Wire Products provides close tolerance wire fabrications using steel and stainless steel. Customized applications include a wide range of wire forms for many different applications. Acme works with wire from .050 to .500 diameter.

CUSTOM "Spring & Wire Form Specialists" - Ace Wire Spring & Form incorporates the latest CNC equipment technology to manufacture compression, extension, torsion springs, complex wire forms, and spring assemblies. We offer consistent quality, lower costs, on-time deliveries, and Design Engineering Assistance. Range from prototypes to long production runs - Family owned & operated since ...

Apex Spring & Stamping is a certified minority owned company that manufacturers springs, stampings, wire forms, clips, and fasteners. Our core industries include automotive, office furniture, medical, recreational, consumer goods, and appliances. We also specialize in value added assembly and prototyping. Our engineering team will ensure your part is both functional and cost-effective. IATF 16949 ...

Smith & Richardson, Inc. is a leading provider of precision machining services, offering an extensive range of capabilities including CNC Swiss machining, Wire EDM machining, vertical and horizontal machining, CNC milling, CNC turning, assembly services, and more. With a strong commitment to quality and innovation, we serve the medical, aerospace, casting, and automotive industries, delivering...

At Elyria Spring & Specialty, LLC, we are proud to offer a wide array of high-quality wire forms and comprehensive solutions tailored to meet the diverse needs of our valued customers. With a rich history of expertise and a steadfast commitment to excellence, we have established ourselves as a trusted leader in the wire forming industry. Our product portfolio encompasses a diverse range of wire...

Here at Anderson Quality Spring Manufacturing, Inc., we take great pride in our position as a leading provider of wire forms, offering a comprehensive range of products, services, and capabilities to meet the diverse needs of our valued clientele. With our unwavering commitment to excellence and extensive expertise in wire forming technology, we stand ready to deliver innovative solutions that...

At New England Spring, we pride ourselves on being a premier provider of high-quality wire forms and comprehensive solutions tailored to meet the diverse needs of our valued customers. With decades of experience and a steadfast commitment to excellence, we have established ourselves as a trusted leader in the wire forming industry. Our product portfolio encompasses a wide range of wire forms,...

More Wire Product Manufacturers

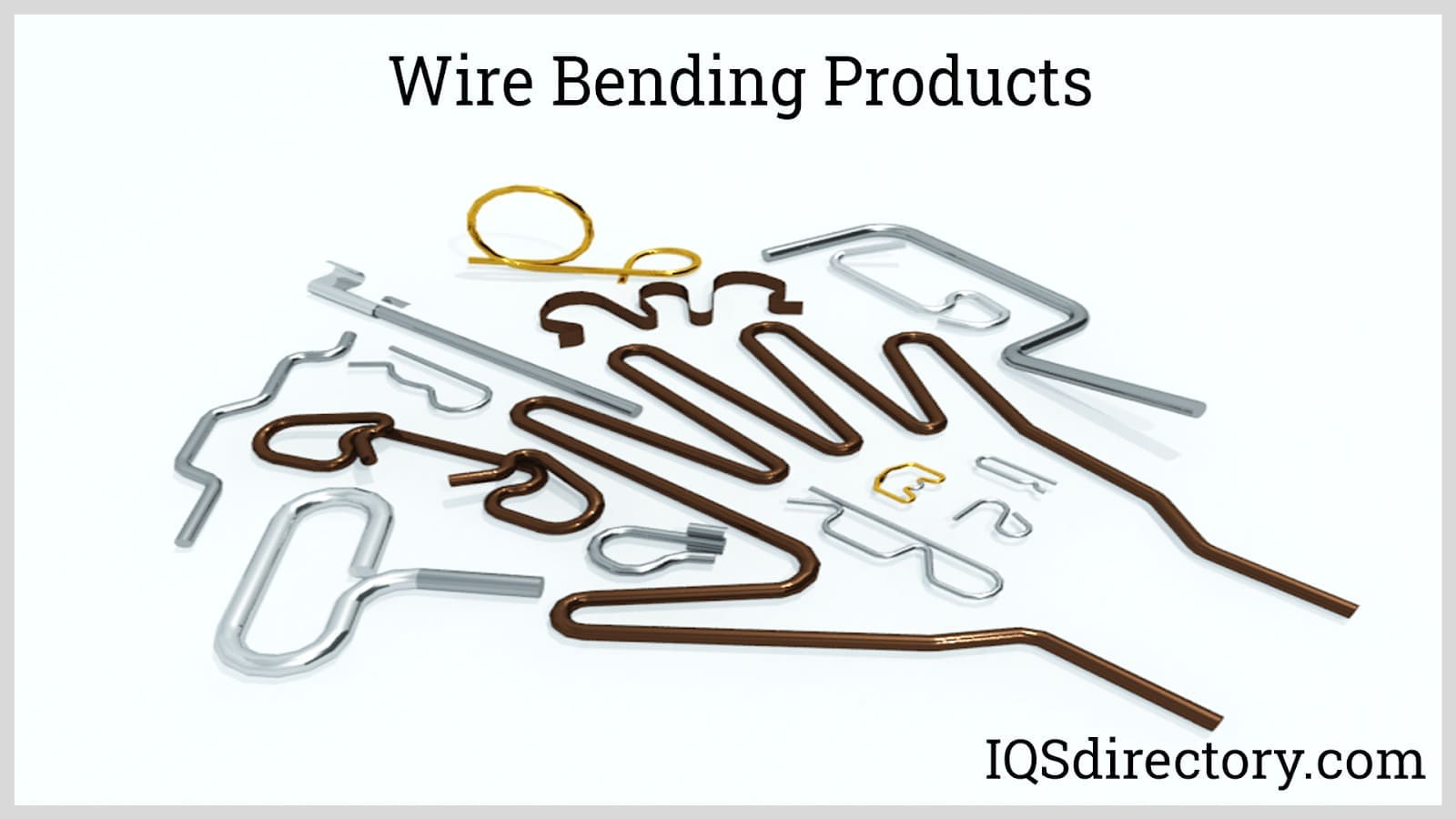

Usually, providers of wire products, specialties, forms, special shapes and forming services provide engineering and design direction, coil or spring making, tool making, fine blanking, wire forming, deep drawing, and four-slide or multi-slide stamping. These suppliers may also provide prototype or short-run services, progressive dies, assembly services, high-volume production, and any extra specialty packaging.

Design of Wire Products

While design or engineering help might include ideas of the trade, manufacturing, engineering costs, methods and material viewpoints, the supplier of wire products could also help in redesigning, improving, re-evaluating, or modernizing the line of prevailing products to improve performance or reduce production costs. Different tools may be used at various stages of the design and fabrication of these products. Meanwhile, special techniques such as fine blanking (the process where wire material is precisely cut) may be employed.

Manufacture of Wire Products

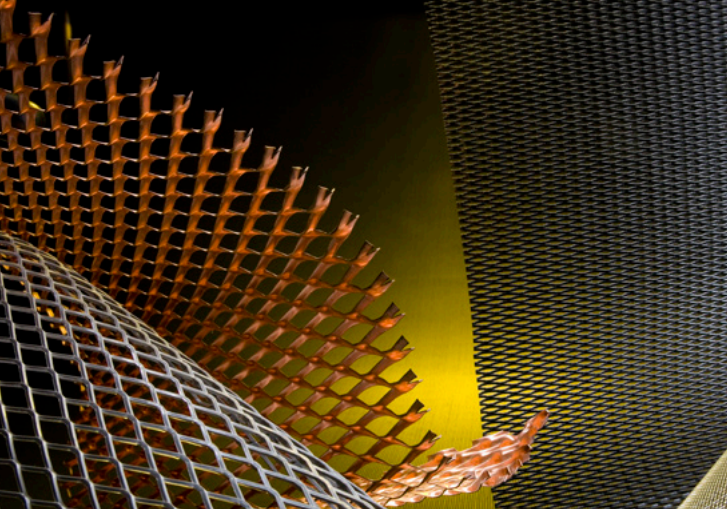

To make wire, stock material is forced or drawn through an array of increasingly small dies which shape the material to a pre-set diameter. These long, thin threads of metal have an oval, round, or shaped cross section as required. Roll forming (or coil making) is the next stage in the procedure where stock metal pieces are then bent, straightened, split or otherwise treated. Secondary treatments like annealing, coating, and painting increase the adaptability of wire products even further. It is imperative to be sure that wire forms are strengthened and finished in a way that will fit the environment where they will be applied.

Coiling and wire forming are two more processes available in making wire products. Coiling includes winding wires into either spirals or rings. Wire forming is a method where wire is stamped into fabricated forms such as springs, clips, hooks, snaps etc. Suppliers of wire products process several materials, including ferrous metals, non-ferrous metals, exotic alloys and metals, precious metals, and plastic. Wire-forming services may also include secondary processes, such as tapping or drilling, CNC machining, EDM cutting, grinding, water or abrasive-jet cutting, or stress relieving (heat treating), before fabricating the final product.

Materials Used in the Manufacture of Wire Products

Stainless steel, brass, steel, iron, tungsten copper, titanium, aluminum, platinum, nickel, or virtually any kind of metal can be utilized in the production of wire. Plastic wire is also used, though less common and, most times, less applicable. It is essential to consider the characteristics of any given material with regards to the use and environment it will be applied. Ductility, malleability, thermal and electrical conductivity, impact and tensile strength, dimensions, magnetism and corrosion resistance must all be examined.

The processing methods used on a wire form must also be of concern since they will impact the above-mentioned characteristics as well as the final wire product.

Application of Wire Products

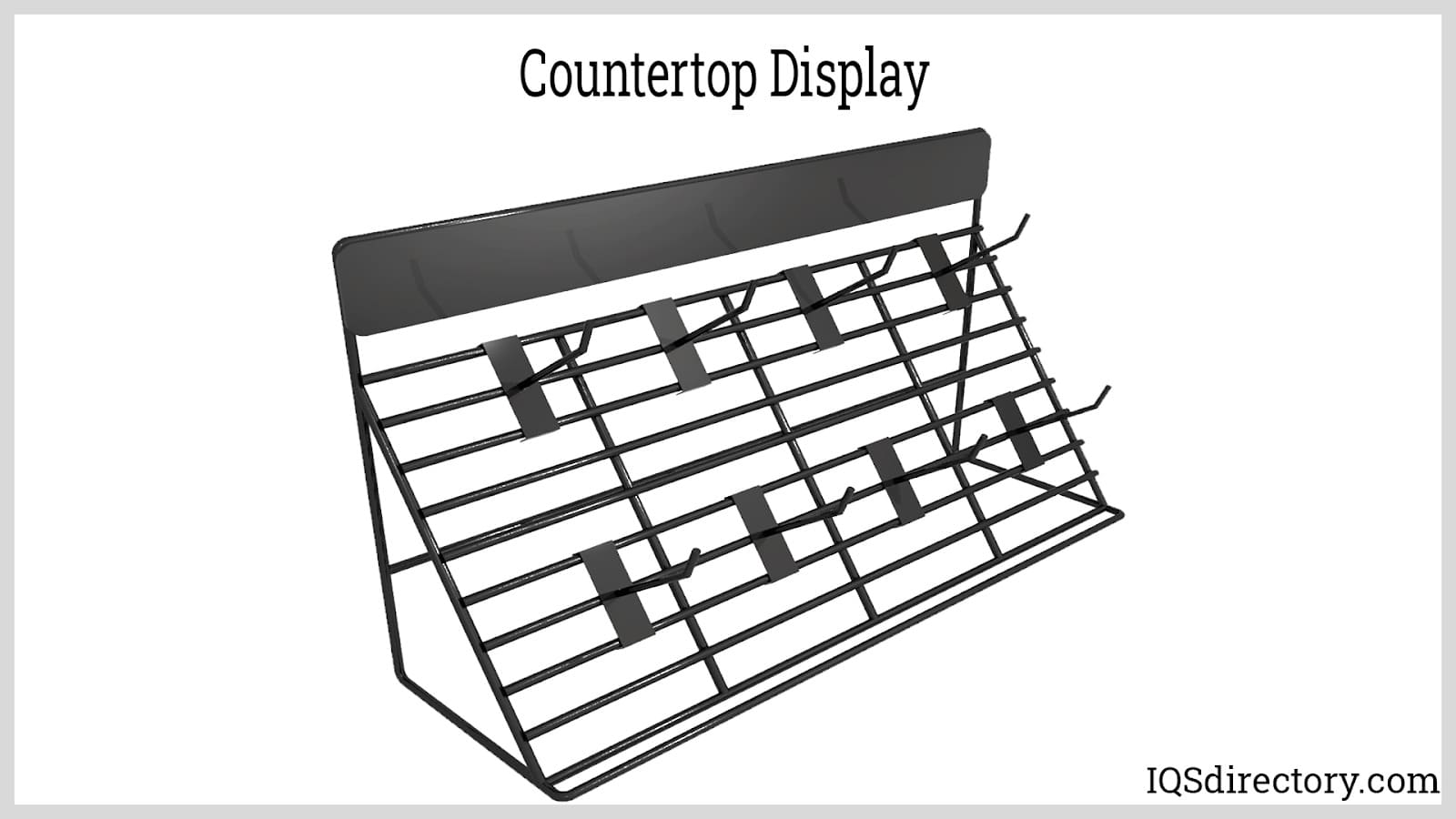

Electronics, music, plumbing, lighting, parts manufacture, material handling, medical, food processing, agricultural, automotive, aerospace, and machining, are just a few industries that use wire forms in daily operations. The reputation of such parts can be credited to their light weight and excellent airflow. Lightweight and easily manufactured, these wire products also increase accessibility and air circulation. Wire parts producers and distributors usually offer these beneficial products in stock or standard fabrications.

Because their applications may differ, many wire-products providers offer custom-made wire machining as well. The capacity for wire product production keeps on expanding as technology enables the creation of gradually smaller and more multifaceted wire apparatus. In addition to an ever-growing number of uses, the variety of materials which may be used in the manufacture and assemblage of wire products has also been upgraded. Ferrous, non-ferrous and various precious metals are frequently used today in the manufacture of wire workings.

Choosing the Correct Wire Products Company

To make sure you have the most beneficial outcome when purchasing wire products from a wire products company, it is important to compare at least 5 companies using our wire product directory. Each wire product company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each wire product company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple wire product companies with the same form.

Cold Headed Parts

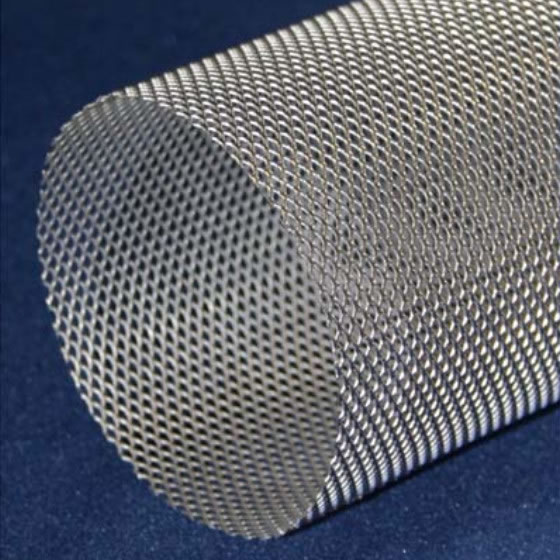

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

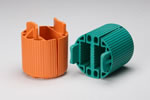

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services