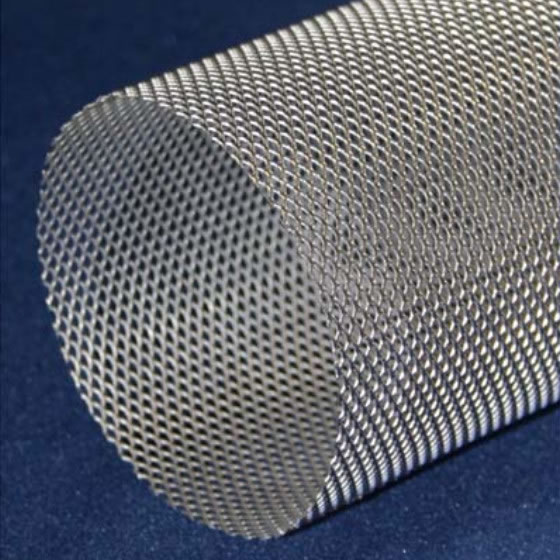

Wire Grids

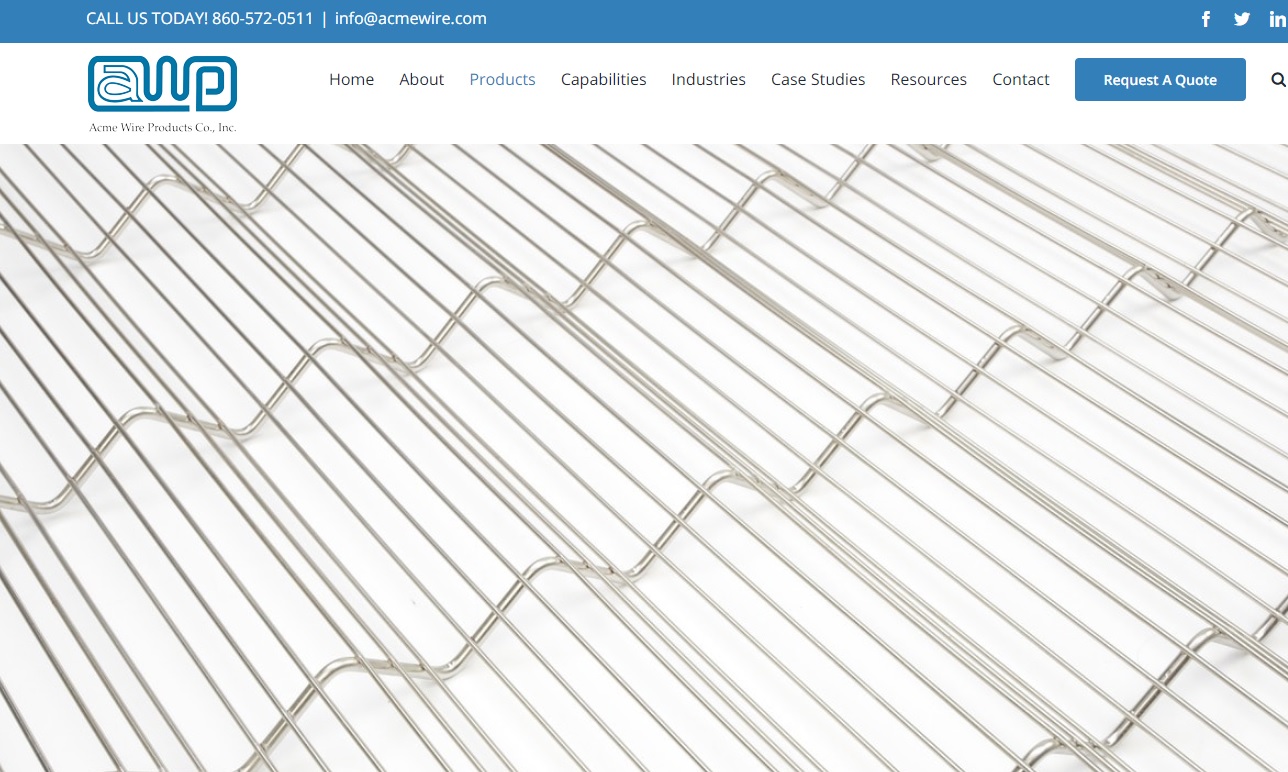

A wire grid, also referred to as a wire grid panel, is a framework of crisscrossed horizontal and vertical wires. Wire grids are very similar to both metal gratings and wire mesh; however, they are on a much larger scale than wire mesh and are formed from wire rather than metal bars as is typical with grating. Read More…

Acme Wire Products provides close tolerance wire fabrications using steel and stainless steel. Customized applications include a wide range of wire forms for many different applications. Acme works with wire from .050 to .500 diameter.

CUSTOM "Spring & Wire Form Specialists" - Ace Wire Spring & Form incorporates the latest CNC equipment technology to manufacture compression, extension, torsion springs, complex wire forms, and spring assemblies. We offer consistent quality, lower costs, on-time deliveries, and Design Engineering Assistance. Range from prototypes to long production runs - Family owned & operated since ...

Apex Spring & Stamping is a certified minority owned company that manufacturers springs, stampings, wire forms, clips, and fasteners. Our core industries include automotive, office furniture, medical, recreational, consumer goods, and appliances. We also specialize in value added assembly and prototyping. Our engineering team will ensure your part is both functional and cost-effective. IATF 16949 ...

Smith & Richardson, Inc. is a leading provider of precision machining services, offering an extensive range of capabilities including CNC Swiss machining, Wire EDM machining, vertical and horizontal machining, CNC milling, CNC turning, assembly services, and more. With a strong commitment to quality and innovation, we serve the medical, aerospace, casting, and automotive industries, delivering...

At Elyria Spring & Specialty, LLC, we are proud to offer a wide array of high-quality wire forms and comprehensive solutions tailored to meet the diverse needs of our valued customers. With a rich history of expertise and a steadfast commitment to excellence, we have established ourselves as a trusted leader in the wire forming industry. Our product portfolio encompasses a diverse range of wire...

Here at Anderson Quality Spring Manufacturing, Inc., we take great pride in our position as a leading provider of wire forms, offering a comprehensive range of products, services, and capabilities to meet the diverse needs of our valued clientele. With our unwavering commitment to excellence and extensive expertise in wire forming technology, we stand ready to deliver innovative solutions that...

At New England Spring, we pride ourselves on being a premier provider of high-quality wire forms and comprehensive solutions tailored to meet the diverse needs of our valued customers. With decades of experience and a steadfast commitment to excellence, we have established ourselves as a trusted leader in the wire forming industry. Our product portfolio encompasses a wide range of wire forms,...

More Wire Grid Manufacturers

Wire grids are useful for a wide range of applications, in industries such as retail, residential, industrial manufacturing and entertainment.

Specific applications of wire grids include point of purchase (POP) displays, lawn and garden accessories, machine guards, shelving and overhead storage systems, walking surfaces that allow safe access to lighting in theaters, wire grid polarizers and wire grid resistors.

Wire grid polarizers are the simplest form of absorptive polarizer, meaning that the grid produces polarized light because of unwanted polarization states that it absorbed during the polarization process. Wire grid resistors are electrical devices that limit current within a circuit. Also referred to as wire-wound resistors, wire grid resistors are used in high-current industrial applications.

Wire grids can be fabricated through a couple of different wire forming processes. One of the more common methods would be through the use of a solid metal frame, which can be a number of different shapes including square, rectangular and trapezoidal. To form the wire grid, metal wire is woven onto the frame in an over and under pattern in order to create a grid that is very similar in style to wire mesh. Another method of fabricating wire grid is through the use of various welding techniques.

There are two main types of welding used are types of spot welding: metal inert gas (MIG) and tungsten inert gas (TIG). The MIG welding process involves the use of electricity from a continuous wire feed in order to melt and join pieces of wire together, while utilizing an inert gas to ensure that the weld is protected from any contamination.

The TIG welding process is similar, but more complex. This process involves the use of a non-consumable electrode formed from tungsten, a shielding inert gas and, at times, a filler material. Some advantages of TIG welding include a stable arc and exceptional weld, while disadvantages are the requirement of significant operator skill and the low speeds of the process. A welded wire grid is much more like a grating, and typically offers a fairly large improvement in strength over woven wire grids.

Cold Headed Parts

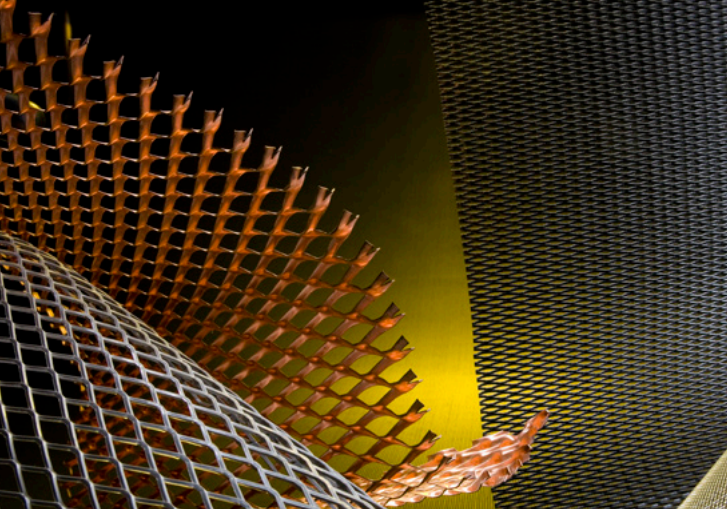

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services