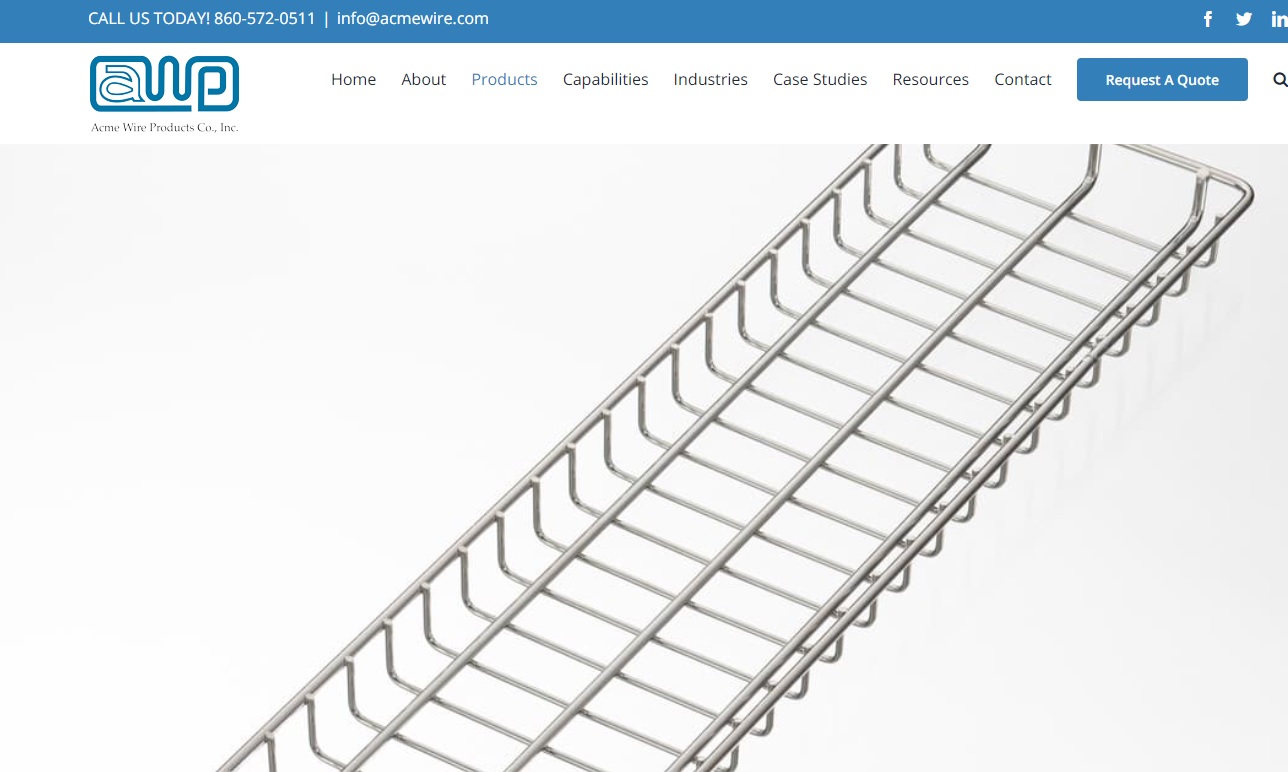

Wire Racks

Wire racks store and display various goods, typically for retail. These items are housed on a bottom surface comprised of many latticed or interlaced metal strands. The phrase “wire rack” more commonly refers to small units or ledges not intended to stand alone, even though they are comparable to wire shelving in that they are both constructed to maximize vertical and horizontal space. Read More…

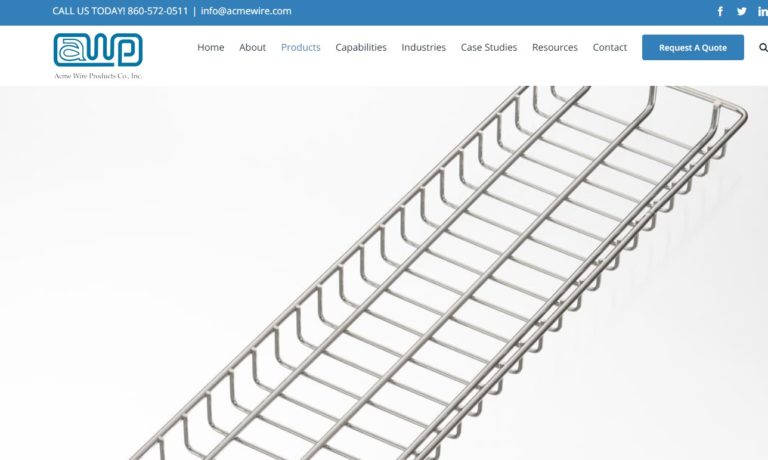

Acme Wire Products provides close tolerance wire fabrications using steel and stainless steel. Customized applications include a wide range of wire forms for many different applications. Acme works with wire from .050 to .500 diameter.

CUSTOM "Spring & Wire Form Specialists" - Ace Wire Spring & Form incorporates the latest CNC equipment technology to manufacture compression, extension, torsion springs, complex wire forms, and spring assemblies. We offer consistent quality, lower costs, on-time deliveries, and Design Engineering Assistance. Range from prototypes to long production runs - Family owned & operated since ...

Apex Spring & Stamping is a certified minority owned company that manufacturers springs, stampings, wire forms, clips, and fasteners. Our core industries include automotive, office furniture, medical, recreational, consumer goods, and appliances. We also specialize in value added assembly and prototyping. Our engineering team will ensure your part is both functional and cost-effective. IATF 16949 ...

Smith & Richardson, Inc. is a leading provider of precision machining services, offering an extensive range of capabilities including CNC Swiss machining, Wire EDM machining, vertical and horizontal machining, CNC milling, CNC turning, assembly services, and more. With a strong commitment to quality and innovation, we serve the medical, aerospace, casting, and automotive industries, delivering...

At Elyria Spring & Specialty, LLC, we are proud to offer a wide array of high-quality wire forms and comprehensive solutions tailored to meet the diverse needs of our valued customers. With a rich history of expertise and a steadfast commitment to excellence, we have established ourselves as a trusted leader in the wire forming industry. Our product portfolio encompasses a diverse range of wire...

Here at Anderson Quality Spring Manufacturing, Inc., we take great pride in our position as a leading provider of wire forms, offering a comprehensive range of products, services, and capabilities to meet the diverse needs of our valued clientele. With our unwavering commitment to excellence and extensive expertise in wire forming technology, we stand ready to deliver innovative solutions that...

At New England Spring, we pride ourselves on being a premier provider of high-quality wire forms and comprehensive solutions tailored to meet the diverse needs of our valued customers. With decades of experience and a steadfast commitment to excellence, we have established ourselves as a trusted leader in the wire forming industry. Our product portfolio encompasses a wide range of wire forms,...

More Wire Rack Manufacturers

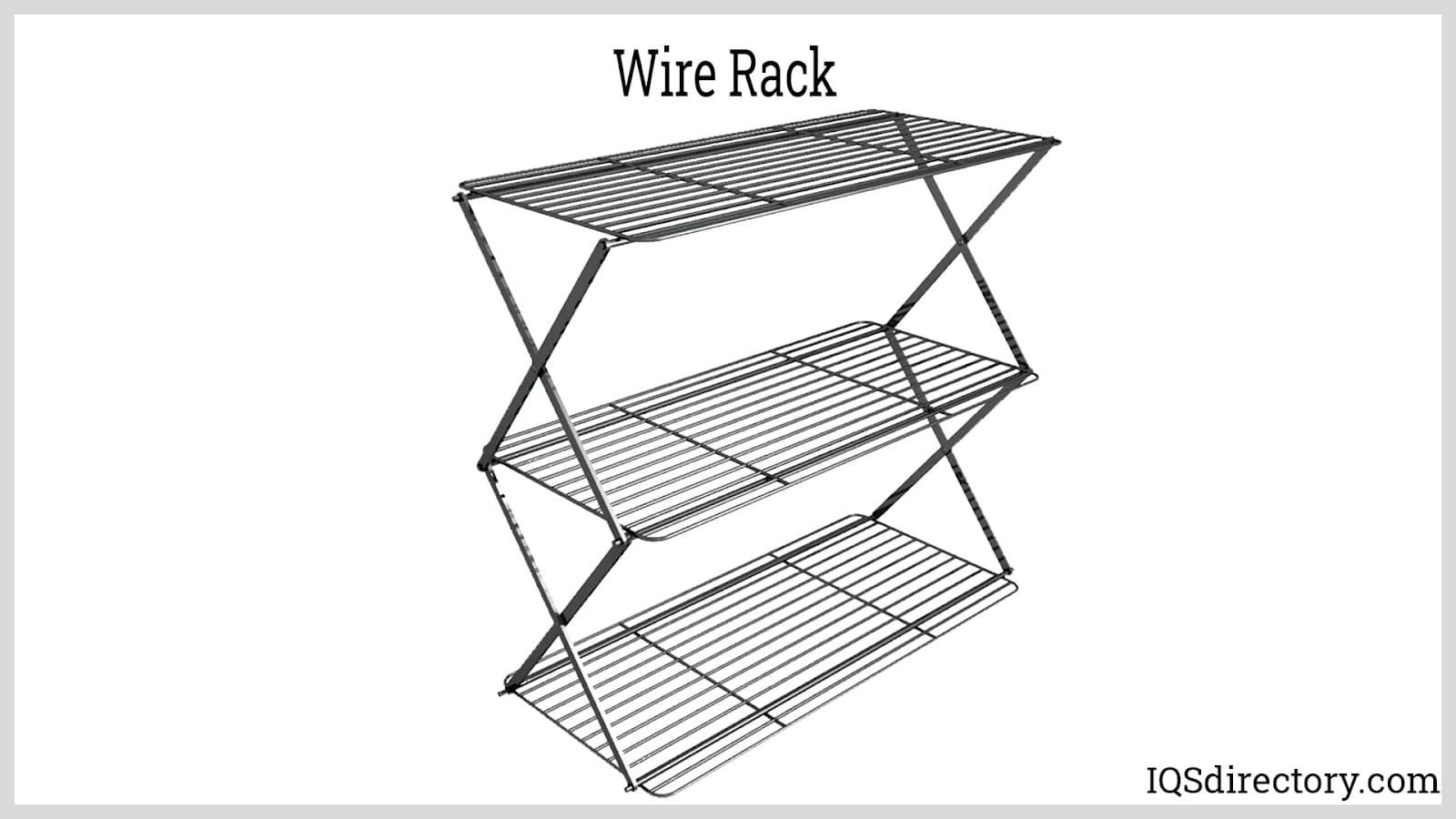

Types of Wire Racks

Merchandising Wire Grid Wall Racks

Typical retail store racks include grid wall fixtures and the industry-standard slat wall. Grid walls are less expensive and lighter than slat walls. Grid-wall wire racks allow for either wall or floor deployment. Following the selection of a wire rack, add-ons, baskets, and hanging hooks can codify the floor layout.

Display Panels for Art

Grid walls can be used as art exhibition panels. These panels are the best choice for outdoor art festivals, galleries, and trade exhibits because they have an effective and lightweight wire frame construction. They quickly hang mirrors, paintings, or other art pieces. Custom configurations are possible thanks to the modular architecture, which is easily accomplished using cotter pins to lock panels together. In addition, an art display panel is reasonably priced and compatible with grid-wall hanging accessories.

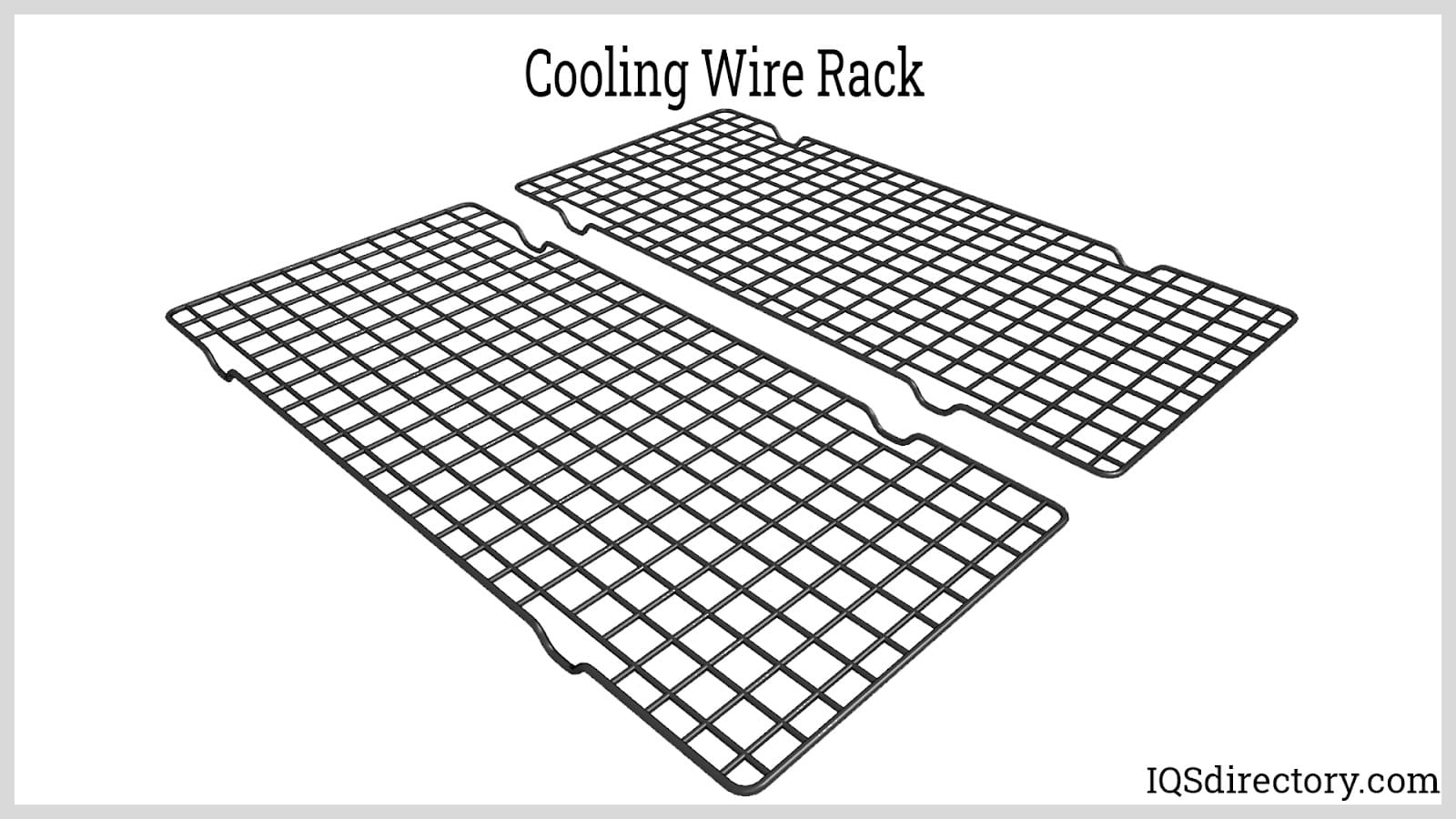

Wire Cooling Racks

A wire cooling rack enables complete air circulation around everything placed on it. As a result, the baked item or pan will cool more quickly than set on a trivet or a countertop. Faster cooling prevents overbaking because a hot pan will continue to bake anything inside of it.

Wire racks are typically formed of square meshes of crisscrossed stainless steel wires. They can also be made of straight and narrowly aligned parallel wires, which keep the baked goods from falling through the rack. A batch of bread, cakes, cookies, or multiple pies can be stored on some cooling racks, while others may have many levels with two or three stacked rows. Cooling racks can be rectangular, square, circular, or oval. Cooling racks can also be used for roasting.

Garment Racks

A retail object used to display clothing items like shirts and coats is a garment or clothes rack. Folding garment wire racks are convenient for various retail uses in clothes stores since they are easy to move and store. In addition, wire forms are ideal for specialized tasks since they can be coiled, angled, bent, or sliced in various ways. Whether made into tiny springs for machinery parts, large chains for hauling bulky objects, or wire racks for keeping goods for retail or commercial use, wire is a versatile material.

Uses of Wire Racks

Wire racks are a great way for companies to display educational materials regarding the goods or services they deal in. Customers can take a brochure on a wire rack located at the business door, on the counter, or within the store. The brochure may include marketing materials for the businesses or any other significant information the owners believe is necessary for the customer to be familiar with.

The architecture of wire racks varies depending on whether they rotate and circle the stand or if they are fixed and need customers to go around them to get what they need. The size of the brochures determines the wire rack's dimensions because some are DL, others are A5, and some are A4. The number of pockets and the size of the pockets determine the height of the stand. For example, a wire rack with three common 1.25-inch-deep pockets might have a maximum height of 7 inches and a maximum base radius of 1.1 inches.

Advantages of Wire Racks

The following are a few advantages of wire racks:

Versatility

Panels can be integrated into wire racks and added or removed depending on the situation. Fixed components can be reconfigured to represent new or increased inventory in addition to the grids working with the provided space. Quickly constructing and removing POP display elements creates efficiency, especially while preparing for a professional exhibition.

Durability

Because only the highest-quality wires are used to make them, wire racks retain their quality even after heavy use. They are an excellent option for exhibiting mirrors, tools, and other large goods because they won't shatter or bend under the weight of the merchandise. They are incredibly lightweight and simple to store and transfer.

Customization and Aesthetic

If necessary, a customized wire rack can incorporate several features and shapes. The main benefit is streamlined, open, and sleek designs that enable product exhibiting. Additional fittings can be created to accommodate any display object, and powder coating will ensure that the hue will meet customer requirements. Manufacturers can collaborate with customers to incorporate their ideas to utilize the desirable qualities of a wire rack.

Economic Advantages of Wire Racks

Wire racks are very cost-effective and high-quality. When durability is factored in, wire racks are a wise investment.

Simple Product Access

Wire racks, like shelving, can be accessed from all four sides. According to this aspect of buyer psychology, customers are more likely to buy an item if they "connect" with it.

Portability

While still built of sturdy metals, wire racks are lighter than other storage solutions, allowing them to be placed quickly on rolling wheels when stacked to make them transportable. This increased movement can enable storage space optimization and necessary changes to the workplace or business's layout.

Simple to Clean

A secure wire rack shields goods from harm. The open design of wire racks prevents dust and debris from building up on them, and when they do, it's simple to clean them off and disinfect them.

Food-safe

In addition to being simple to clean, wire racks may be used for cold storage in butcher shops and restaurants because the mesh allows for the best possible circulation of cold air around the products, resulting in better-quality goods with a longer shelf life. For improved cleanliness, antifungal and antimicrobial epoxy may also be applied to wire racks. For many different purposes, forming is advantageous.

Choosing the Proper Wire Rack Supplier

To make sure you have the most positive outcome when purchasing wire racks from a wire rack supplier, it is important to compare at least 4 companies using our list of wire rack suppliers. Each wire rack supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each wire rack business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple wire rack businesses with the same message.

Cold Headed Parts

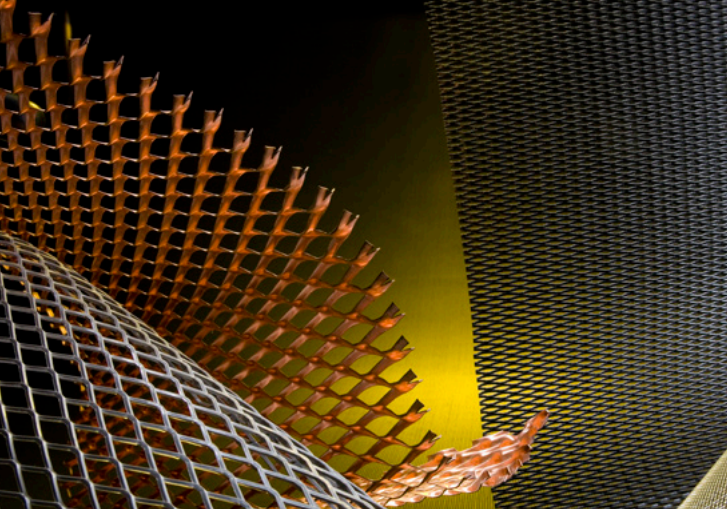

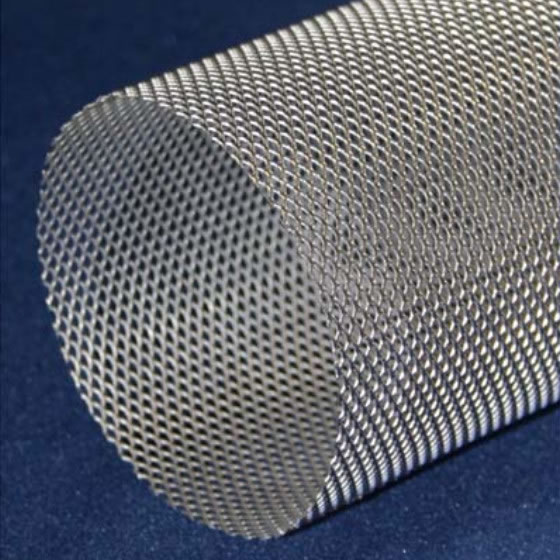

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services