The technique of bending metal wire into useful components like springs, fasteners, and retaining rings is known as wire forming. The term “wire” generally refers to coilable, flexible metal strands. Wire can be flat or curved to have square, rectangular, or trapezoidal cross sections; however, the cross-section is typically round. Read More…

Acme Wire Products provides close tolerance wire fabrications using steel and stainless steel. Customized applications include a wide range of wire forms for many different applications. Acme works with wire from .050 to .500 diameter.

CUSTOM "Spring & Wire Form Specialists" - Ace Wire Spring & Form incorporates the latest CNC equipment technology to manufacture compression, extension, torsion springs, complex wire forms, and spring assemblies. We offer consistent quality, lower costs, on-time deliveries, and Design Engineering Assistance. Range from prototypes to long production runs - Family owned & operated since ...

Apex Spring & Stamping is a certified minority owned company that manufacturers springs, stampings, wire forms, clips, and fasteners. Our core industries include automotive, office furniture, medical, recreational, consumer goods, and appliances. We also specialize in value added assembly and prototyping. Our engineering team will ensure your part is both functional and cost-effective. IATF 16949 ...

Smith & Richardson, Inc. is a leading provider of precision machining services, offering an extensive range of capabilities including CNC Swiss machining, Wire EDM machining, vertical and horizontal machining, CNC milling, CNC turning, assembly services, and more. With a strong commitment to quality and innovation, we serve the medical, aerospace, casting, and automotive industries, delivering...

At Elyria Spring & Specialty, LLC, we are proud to offer a wide array of high-quality wire forms and comprehensive solutions tailored to meet the diverse needs of our valued customers. With a rich history of expertise and a steadfast commitment to excellence, we have established ourselves as a trusted leader in the wire forming industry. Our product portfolio encompasses a diverse range of wire...

Here at Anderson Quality Spring Manufacturing, Inc., we take great pride in our position as a leading provider of wire forms, offering a comprehensive range of products, services, and capabilities to meet the diverse needs of our valued clientele. With our unwavering commitment to excellence and extensive expertise in wire forming technology, we stand ready to deliver innovative solutions that...

At New England Spring, we pride ourselves on being a premier provider of high-quality wire forms and comprehensive solutions tailored to meet the diverse needs of our valued customers. With decades of experience and a steadfast commitment to excellence, we have established ourselves as a trusted leader in the wire forming industry. Our product portfolio encompasses a wide range of wire forms,...

More CNC Wire Forming Manufacturers

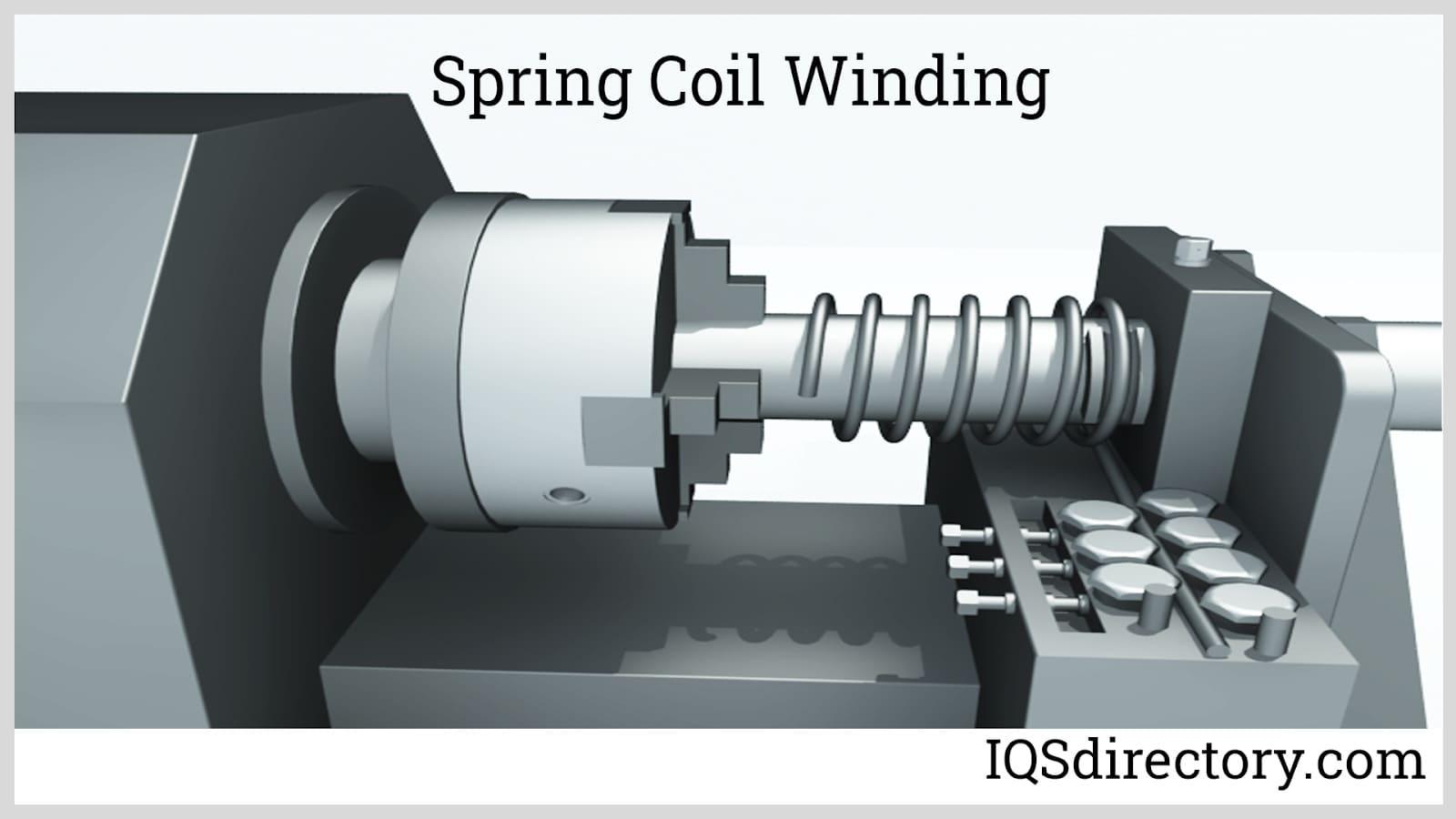

CNC wire forming, also known as wire bending, is an advanced method for shaping metal into predetermined or unique shapes for product manufacturing. Machines create wire forms, which come in different sizes and shapes, by heat treatment, cutting, and bending. Utilizing standardized equipment, CNC wire-forming machines change the wire's shape, size, and dimension to produce intricate two-dimensional and three-dimensional items.

Wire shaping is essential in many industries, including the automotive, aircraft, building, military, commercial, and electrical sectors. Several materials produce wire shapes, including steel, stainless steel, copper, aluminium, and several alloys. With CNC wire forming, you may create custom designs, spend less time setting up, produce new or changed product parts more quickly, and pay less per piece, even for small to medium-sized production runs.

Working Principle of CNC Machine Tools

The computer in the CNC device encodes information recorded in a series of processing using digital and character encoding. Then it sends commands to the machine tool's spindle, feed, and other actuators through a programmable controller. The machine tool body then acts following these instructions when feedback devices are detected, and the work piece processing necessary for the tool's intended use is then determined. Finally, the information is entered into the wire-forming equipment once the materials, dimensions, and shapes have been decided upon. This implies that the machines, which can produce the identical spring or wire form up to thousands of times each hour, already have each bend and twist pre-programmed (allowing for a quick turnaround, at times, within a few days of order).

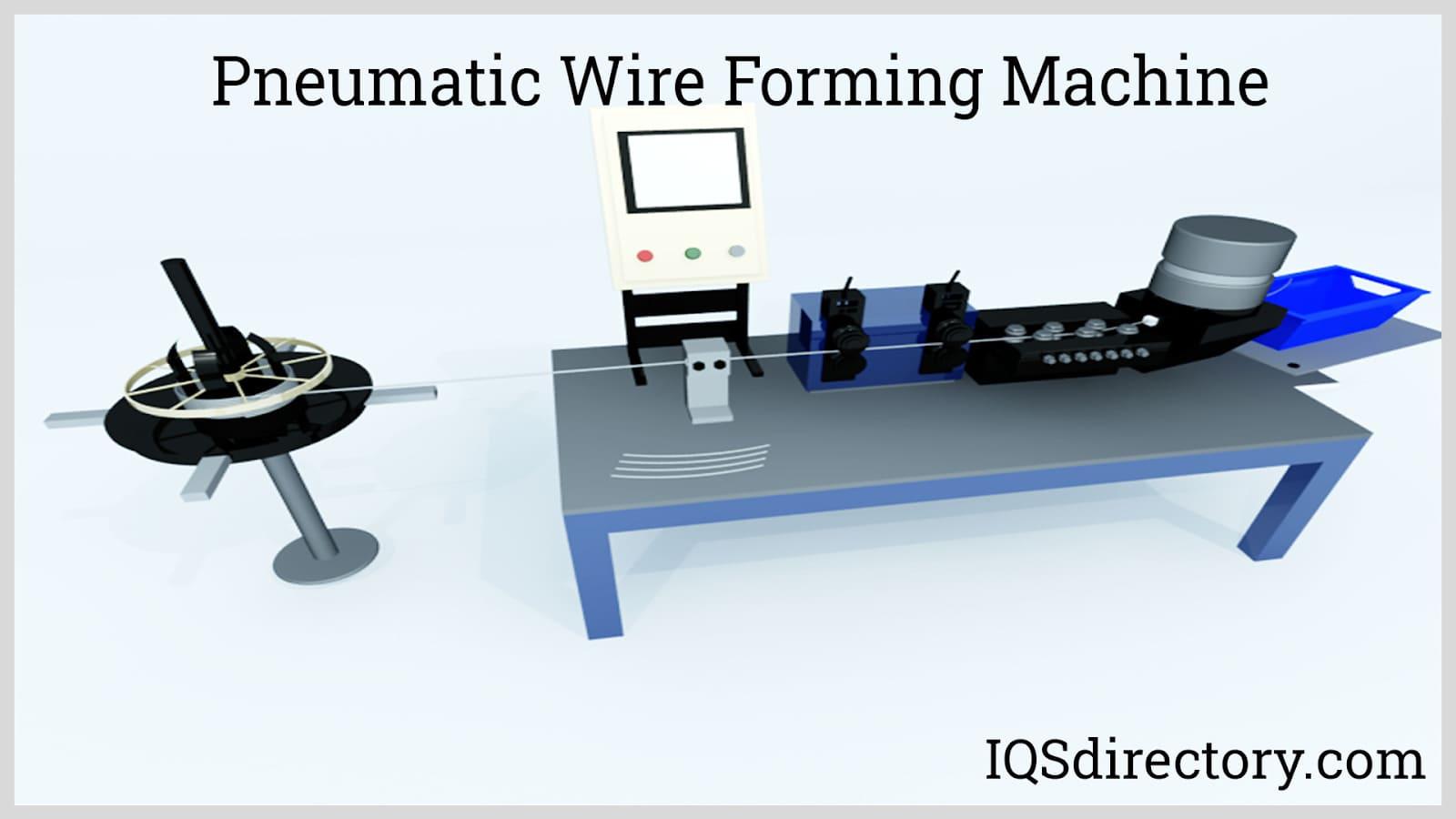

Before beginning the manipulation process, the wire is uncoiled from a spool and passed through a series of wheels intended to straighten it. The wire is then shaped using several dies and pins until the finished portion is achieved and snipped off with a blade.

Wire Forming Materials

Steel, stainless steel, aluminium, copper, nickel, and other alloys are among the metals used in wire making. Different qualities of these metals affect how the wire is formed.

For springs and high-strength items, wire shaping frequently uses carbon steel alloys. Carbon steel is cheap, durable, and conductible. More carbon is added to carbon steel, increasing its strength and hardness; high carbon steel wire is frequently referred to as music wire. Low-carbon steel is better suited for low-stress springs since higher-carbon steels are less flexible and more brittle. However, carbon steel is not appropriate for parts meant for a damp environment because it is also susceptible to corrosion. Carbon steel resists rusting better because stainless steel contains more susceptible metals like chromium.

Compared to steel, copper is stronger and more flexible. In addition, it is useful for electrical applications since it is a great conductor with high thermal conductivity.

Bronze resists corrosion and is a superior conductor. Therefore, it is frequently employed to create conductive springs.

Although it is not as strong as steel, aluminium is more pliable, light, and corrosion-resistant than steel.

Nickel has good corrosion resistance and maintains stability across a broad temperature range. In addition, when non-magnetic components are required, nickel is a good substitute for steel since the nickel alloys used in wire formation are both non-magnetic and poor electrical conductors.

Advantages of CNC Wire Forming

"Computer numerically controlled" (CNC) refers to automated machinery. Unmatched by any other wire-forming technique, CNC wire forming is a highly adaptable technology that allows for two- or three-dimensional bending. As a result, manufacturers can typically handle production changeovers from one run to another in under an hour. However, pre-programmed manufacture of parts and components with unique patterns, arrangements, and dimensions is where CNC wire forming shines. As a result, products can be produced more accurately and in greater volume, which results in less waste.

The ability of CNC wire-forming procedures to operate in tandem with conventional wire-forming equipment is another benefit. These devices can conduct automated tasks more successfully by adapting CNC programming. A wire-forming machine can fabricate wire parts and components constantly once it has been CNC coded. Depending on the tools and design complexity, it can even create full wire shapes. With other wire forming equipment, CNC compatibility boosts output and guarantees precision that manually driven devices cannot match.

Industrial Applications of Wire Forming

The manufacture of numerous components for countless applications depends on wire shaping. Various items are produced using CNC wire form manipulation, including motor mounts, wire baskets, applications for power transmission, pins, clips, springs, wire screens, grills, coils, guide wires, wire stents, tubes, carts, and filters.

Compression coil springs and volute springs are used in suspension applications by industries including the automotive. Tension and torsion springs are manufactured for more delicate applications like valves, clutches, and gear changes. Metal baskets for washing machines and other common components are made in the healthcare industry using CNC wire-forming tools. Other medical supplies can be anything from a straightforward gauged tray to hand-held pliers. By using CNC wire shapes, electronic and electrical fittings are created. Wire forms make various household items, including clothing hangers, screen doors, and mouse traps. The industries that depend on CNC wire forming to manufacture and manufacture products essential to their operations include commercial and retail, construction and hardware, aerospace, energy, and agriculture.

Conclusion

Manufacturers can produce large quantities of goods more accurately thanks to CNC wire forming than conventional wire forming techniques. In addition, it enables producers to quickly fabricate pre-programmed two-dimensional and three-dimensional parts and components for products in different industries.

Choosing the Proper CNC Wire Forming Manufacturer

To make sure you have the most productive outcome when purchasing CNC wire-forming from a CNC wire-forming manufacturer, it is important to compare at least 4 manufacturers using our CNC wire-forming directory. Each CNC wire-forming manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each CNC wire-forming business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple CNC wire-forming businesses with the same quote.

Cold Headed Parts

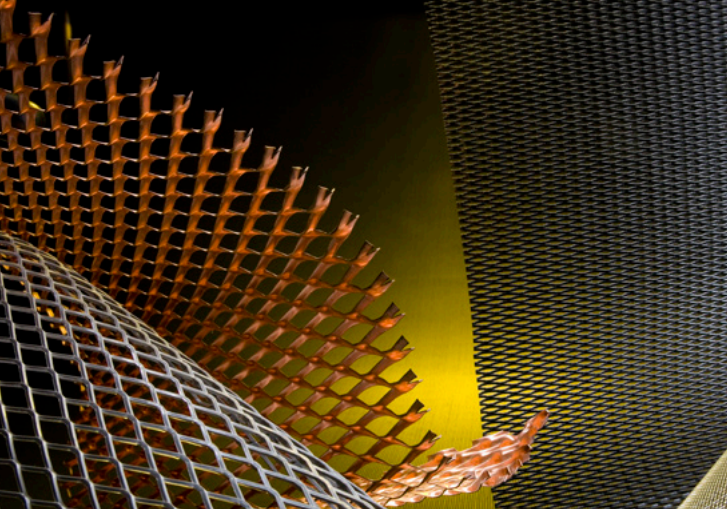

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

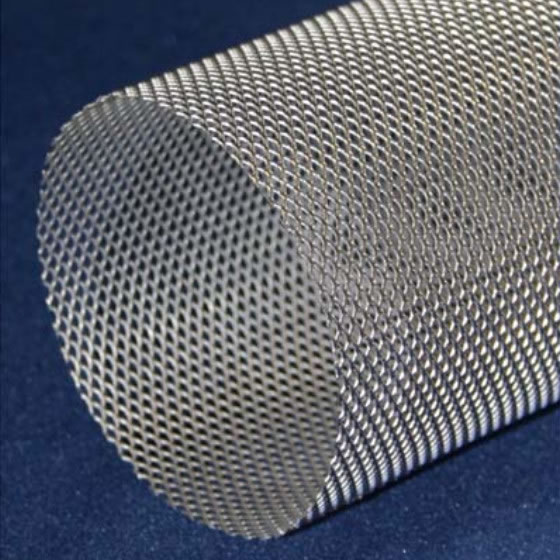

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services