CNC bending machines work with pre-existing machines to fabricate and mass-produce bends in wire. Machines can program the pre-existing machine to bend wire in very specific ways. Read More…

Acme Wire Products provides close tolerance wire fabrications using steel and stainless steel. Customized applications include a wide range of wire forms for many different applications. Acme works with wire from .050 to .500 diameter.

CUSTOM "Spring & Wire Form Specialists" - Ace Wire Spring & Form incorporates the latest CNC equipment technology to manufacture compression, extension, torsion springs, complex wire forms, and spring assemblies. We offer consistent quality, lower costs, on-time deliveries, and Design Engineering Assistance. Range from prototypes to long production runs - Family owned & operated since ...

Apex Spring & Stamping is a certified minority owned company that manufacturers springs, stampings, wire forms, clips, and fasteners. Our core industries include automotive, office furniture, medical, recreational, consumer goods, and appliances. We also specialize in value added assembly and prototyping. Our engineering team will ensure your part is both functional and cost-effective. IATF 16949 ...

Smith & Richardson, Inc. is a leading provider of precision machining services, offering an extensive range of capabilities including CNC Swiss machining, Wire EDM machining, vertical and horizontal machining, CNC milling, CNC turning, assembly services, and more. With a strong commitment to quality and innovation, we serve the medical, aerospace, casting, and automotive industries, delivering...

At Elyria Spring & Specialty, LLC, we are proud to offer a wide array of high-quality wire forms and comprehensive solutions tailored to meet the diverse needs of our valued customers. With a rich history of expertise and a steadfast commitment to excellence, we have established ourselves as a trusted leader in the wire forming industry. Our product portfolio encompasses a diverse range of wire...

Here at Anderson Quality Spring Manufacturing, Inc., we take great pride in our position as a leading provider of wire forms, offering a comprehensive range of products, services, and capabilities to meet the diverse needs of our valued clientele. With our unwavering commitment to excellence and extensive expertise in wire forming technology, we stand ready to deliver innovative solutions that...

At New England Spring, we pride ourselves on being a premier provider of high-quality wire forms and comprehensive solutions tailored to meet the diverse needs of our valued customers. With decades of experience and a steadfast commitment to excellence, we have established ourselves as a trusted leader in the wire forming industry. Our product portfolio encompasses a wide range of wire forms,...

More CNC Wire Bending Manufacturers

CNC Wire Bending machines, which are generally automatic, can be made to have a single or double head, and can be made fully electric. They can also be equipped with integrated load and unload capabilities.

They accept many types of wire, such as aluminum and stainless steel, to fit the needs of the consumer. Bends can be set to custom angles. They may come with one or more reversible bending heads. They have clockwise or counterclockwise rotation and variable radius.

Double-headed bending machines are well-suited to performing machining operations on a medium and long workpieces with many bends. Symmetrical and/or closed workpieces also work well. These are generally used in automotive, appliances, internal and external furnishing, shop and supermarket equipment and military sectors.

CNC Wire Bending machines may be ordered with accessories like chamfering, pressing, decoiling, marking, end forming, drilling, marking or threading components. Both 2D and 3D machines are available, and they can both expand to accommodate accessory modules.

CNC Wire Bending machines have many advantages. Electric wire bending machines, in particular, run more inexpensively because they require about half of the energy consumed by electro-hydraulic machines.

All CNC Wire Bending machines save money through efficiency increase, by easily recreating the programmed design on a robust and continuous basis. It also decreases the number of workers needed to complete a function. The CNC Wire Bending machine produces highly accurate parts and it is more functional than a 3D printer.

Accessories can often be built in-line, allowing for turn-key end product manufacturing. This machine is super beneficial to a number of markets. In addition to those already mentioned, CNC Wire Bending supports numerous other OEM manufacturing applications, such as air and space, household appliances, lawn and garden, construction, HVAC, storage and material handling.

Cold Headed Parts

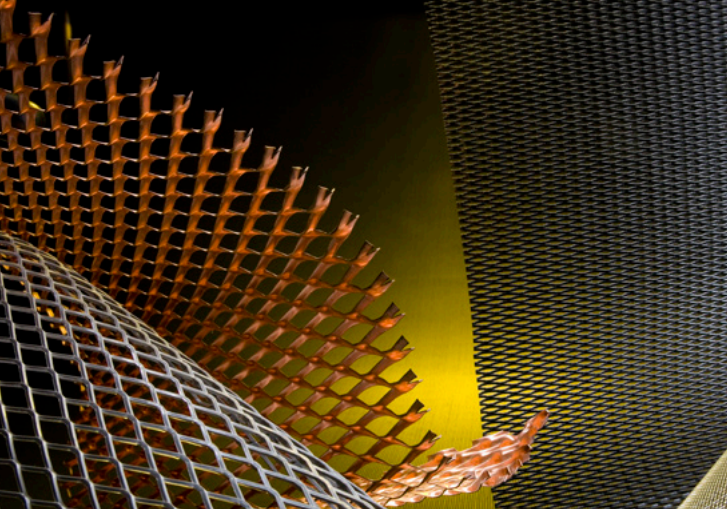

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

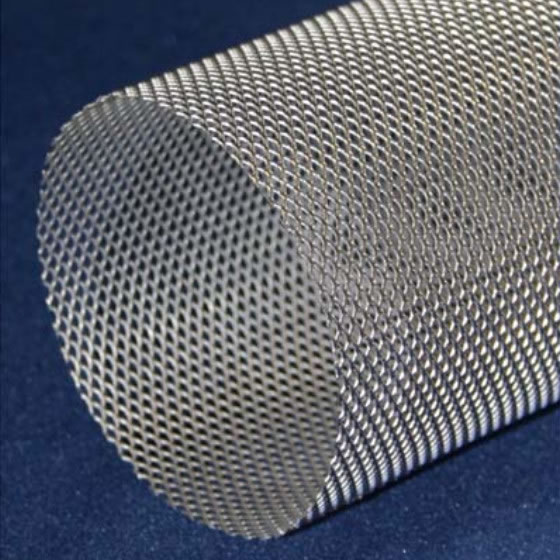

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services