HyTech Spring and Machine Corporation

HyTech Spring and Machine CorporationRequest A Quote

Plainwell, MIWelcome to HyTech Spring and Machine Corporation, a leading provider of wire forms solutions with unmatched precision and expertise. With our state-of-the-art facility and cutting-edge technology, we specialize in manufacturing custom wire forms for even the most demanding applications. At HyTech Spring and Machine Corporation, we understand the critical role that accuracy and repeatability play in wire form production. Our advanced manufacturing processes and equipment enable us to process wireform diameters as small as 0.0015 inches while maintaining uncompromising precision and consistency. This level of precision allows us to create wire forms that meet the most stringent requirements of our customers. Our facility is equipped with a range of the latest CNC wireforming systems, integrated with advanced software and automation capabilities. This combination of technology and expertise empowers us to handle complex wire forming projects with ease. From intricate shapes and bends to complex geometries, we have the capabilities to manufacture custom wire forms that precisely match your specifications. At HyTech Spring and Machine Corporation, we pride ourselves on our ability to tackle the most challenging applications. We work closely with our customers to understand their unique requirements and develop innovative wire form solutions that address their specific needs. Our experienced team of engineers and technicians collaborates with you throughout the entire process, from design and prototyping to production and delivery, ensuring that the final product meets and exceeds your expectations. Quality is deeply ingrained in our company culture. We adhere to stringent quality control measures at every stage of the manufacturing process to ensure that each wire form leaving our facility is of the highest standard. Our commitment to quality extends to our team, who undergo regular training to stay updated with the latest industry practices and advancements. Contact us today to discuss your wire form requirements. Experience the HyTech Spring and Machine Corporation difference, where precision, expertise, and outstanding customer service converge to provide you with the wire form solutions you need for even the most challenging applications.

Cold Headed Parts

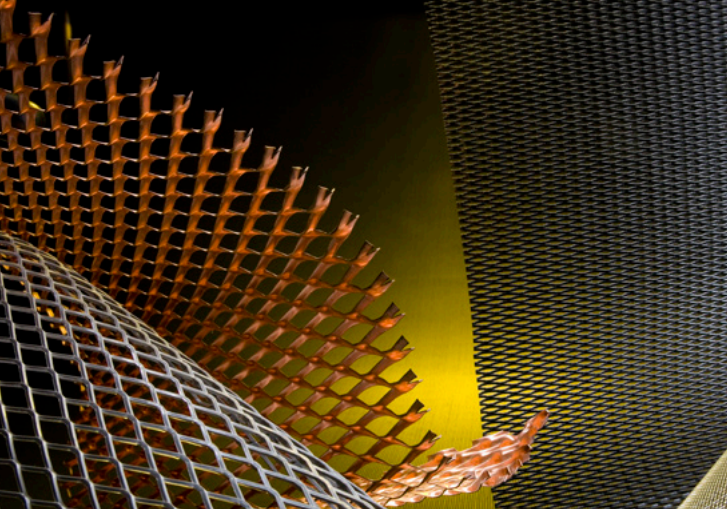

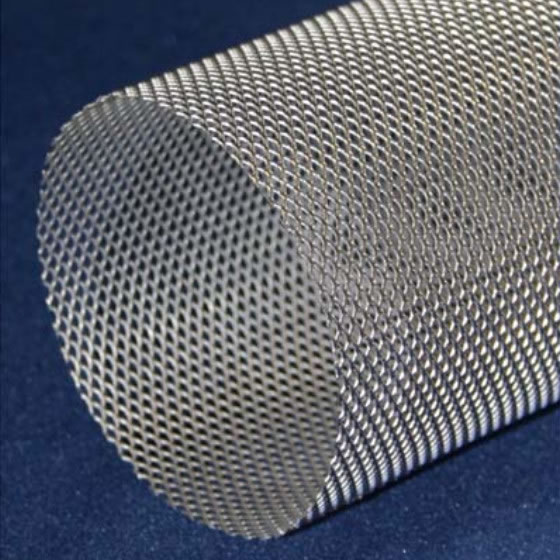

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services