R & D Spring and Stamping, Inc.

R & D Spring and Stamping, Inc.Request A Quote

Chino, CAAt R & D Spring and Stamping, we take immense pride in our expertise and dedication to manufacturing high-quality springs and wire forms. With a strong focus on wire forms products and services, we have become a leading name in the industry. Our specialized offerings include torsion springs, extension springs, and compression springs, catering to a wide range of industrial applications. Since our inception in 1982, we have amassed years of valuable experience, which has honed our skills and allowed us to refine our processes to perfection. Our extensive knowledge of the industry enables us to understand and meet the diverse needs of our customers, making us a reliable partner for all their spring product requirements. In our production facilities, we utilize cutting-edge technology and modern machinery to process wire diameters ranging from .003 to .156, ensuring precision and consistency in every product we manufacture. Our commitment to innovation drives us to continually upgrade our equipment and adopt the latest industry practices to stay ahead of the curve. At R & D Spring and Stamping, our dedicated team of engineers, technicians, and skilled craftsmen work collaboratively to design and produce wire forms that exceed industry standards. We understand the critical role that springs and wire forms play in various applications, which is why we focus on producing products with impeccable accuracy and unparalleled performance. As a testament to our commitment to quality, our manufacturing processes undergo rigorous quality control measures at every stage. We ensure that each spring and wire form leaving our facility meets the highest standards, adheres to industry regulations, and performs flawlessly in the intended applications. Whether you require custom-made wire forms or standard springs, our versatile production capabilities and experienced team are equipped to handle projects of all sizes and complexities. When you choose R & D Spring and Stamping as your partner, you can rest assured that our years of experience will work tirelessly to meet and exceed your spring product needs, providing you with solutions that inspire confidence and deliver results.

Cold Headed Parts

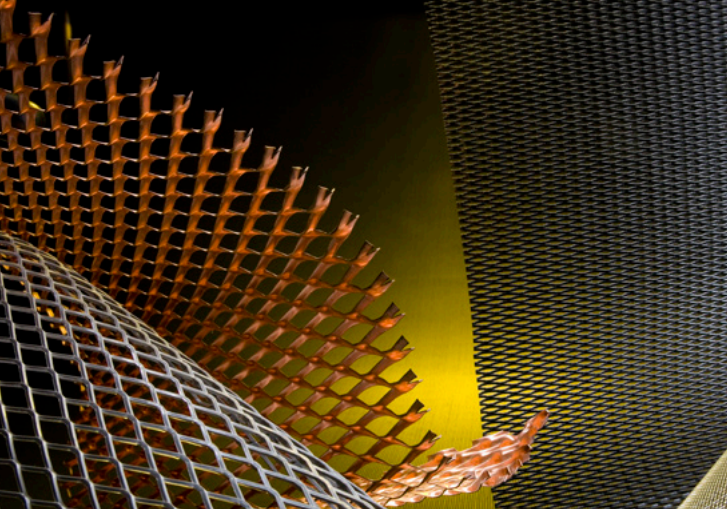

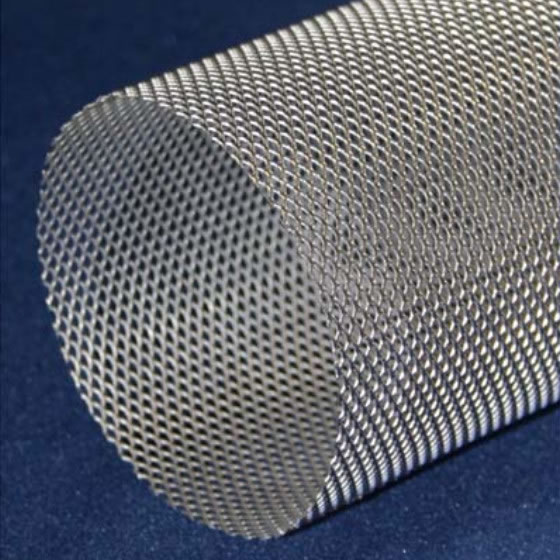

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services