Stanley Spring and Stamping Corporation

Stanley Spring and Stamping CorporationRequest A Quote

Chicago, ILStanley Spring and Stamping Corporation is a renowned company specializing in the production of wire forms. With a focus on utilizing cutting-edge forming processes and advanced machining capabilities, we are committed to delivering high-quality wire form products that meet the specific requirements of our customers. Our state-of-the-art forming processes, including four-slide, multiple planes, and multiple bend techniques, enable us to create wire forms with exceptional precision and complexity. We have invested in the latest machinery and technology to ensure that our manufacturing processes are efficient and accurate, resulting in wire forms that meet the highest standards of quality. At Stanley Spring and Stamping Corporation, we understand that each customer has unique needs when it comes to wire form shapes and sizes. That is why we offer a comprehensive range of machining capabilities, including coin, chamfer, pierce, and swage machining. These capabilities allow us to deliver wire forms with the exact configurations required by our customers, ensuring a precise fit and optimal functionality. When it comes to wire dimensions, our expertise extends to a maximum wire diameter of up to .25". We are also capable of working with flat wire widths of up to .188" and wire thicknesses of up to .188". Whether our customers require flattened, pierced, or swedged configurations, we have the capability to handle their specific needs. Moreover, at Stanley Spring and Stamping Corporation, we work with a variety of materials to meet diverse industry requirements. Our maximum wire length capabilities extend up to 36" in galvanized basic, stainless steel, brass, copper, and bronze. This extensive material selection ensures that we can cater to a wide range of applications and industries, providing our customers with versatile wire form solutions. Our team of skilled engineers, technicians, and craftsmen has extensive experience in wire forming and possesses in-depth knowledge of various materials and manufacturing processes. We collaborate closely with our customers to understand their specific project requirements, providing expert guidance and support throughout the entire production process. From design assistance to prototyping, production, and finishing, we offer comprehensive services to ensure that our customers' wire form needs are met with the highest level of precision and quality. At Stanley Spring and Stamping Corporation, we are committed to delivering excellence in every aspect of our work. We continuously invest in research and development to stay ahead of industry trends and technological advancements. Our commitment to innovation allows us to offer cutting-edge solutions that meet the evolving needs of our customers. When you choose Stanley Spring and Stamping Corporation as your wire form partner, you can expect exceptional quality, precise manufacturing, and reliable service. Contact us today to discuss your wire form requirements, and let us demonstrate our capabilities in delivering superior wire form solutions tailored to your specific needs.

Cold Headed Parts

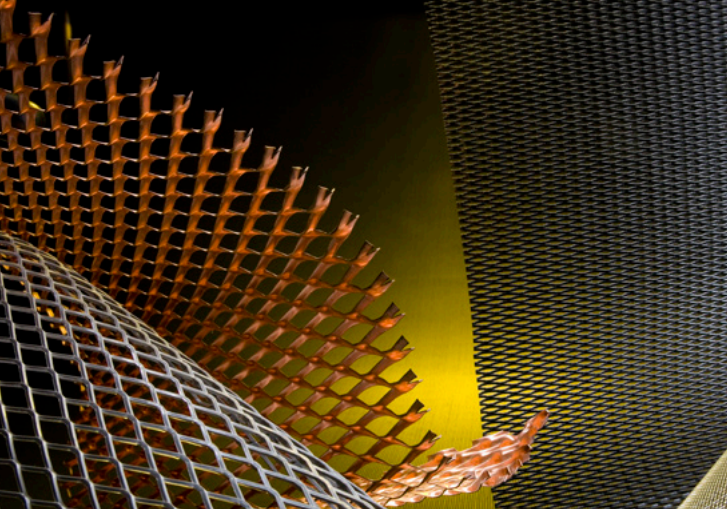

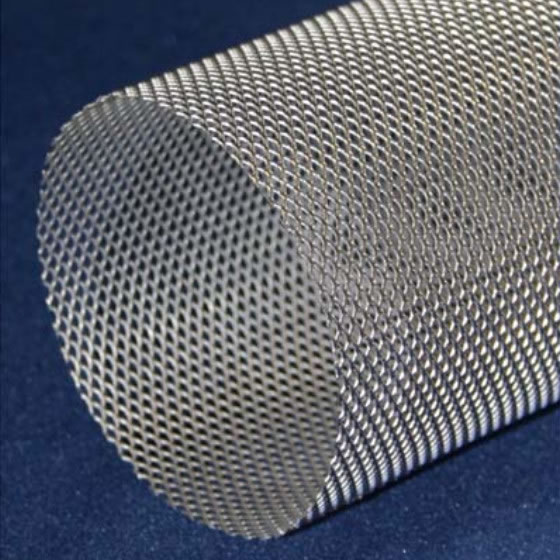

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services