Tollman Spring Company, Inc.

Tollman Spring Company, Inc.Request A Quote

Bristol, CTWe are Tollman Spring Company, Inc., a world-class manufacturer of high-quality compression, extension, and torsion springs, four-slide stampings, and wire forms. With a strong presence throughout the United States, we have earned a reputation for our unwavering commitment to exceptional quality and outstanding service. At Tollman, we operate from three state-of-the-art manufacturing facilities, where a team of over 100 highly skilled employees work tirelessly to meet the diverse needs of our customers. Our expertise lies in the production of wire forms, a critical component used in various industries and applications. We specialize in designing, engineering, and manufacturing wire forms that meet the highest standards of precision and durability. Whether it's a simple wire shape or a complex custom design, we have the capabilities to deliver top-notch wire forms tailored to the specific requirements of our clients. As a trusted partner to a wide range of customers, our clientele spans from some of the world's largest corporations, such as General Electric, to local manufacturers of products like bird feeders. We understand the unique needs and challenges faced by businesses of all sizes, and we pride ourselves on delivering personalized solutions that exceed expectations. One of the key factors that sets Tollman apart is our unwavering commitment to quality. We adhere to stringent quality control measures at every stage of production, ensuring that each wire form leaving our facilities meets the highest standards of performance and reliability. Our dedicated quality assurance team conducts rigorous inspections and tests to guarantee that our products consistently meet or exceed customer specifications. At Tollman Spring Company, we are driven by innovation and continuous improvement. We invest in the latest manufacturing technologies and equipment, enabling us to stay at the forefront of the industry and deliver cutting-edge wire form solutions. Our team embraces new challenges and collaborates closely with customers to develop innovative designs that optimize performance, efficiency, and cost-effectiveness. In summary, Tollman Spring Company, Inc. is a world-class manufacturer of high-quality wire forms, compression, extension, and torsion springs, as well as four-slide stampings. With a strong emphasis on quality and customer service, we serve a diverse range of customers, from global corporations to local manufacturers. Our state-of-the-art facilities, dedicated team of skilled professionals, and commitment to innovation make us the preferred choice for wire form solutions in the United States and beyond.

Cold Headed Parts

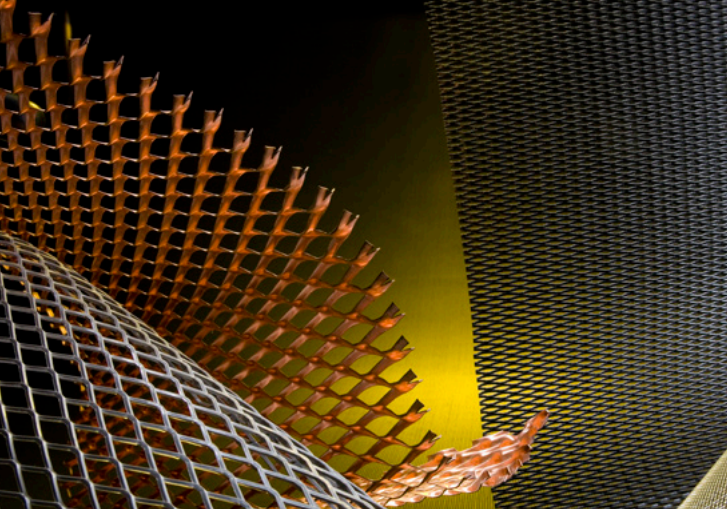

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

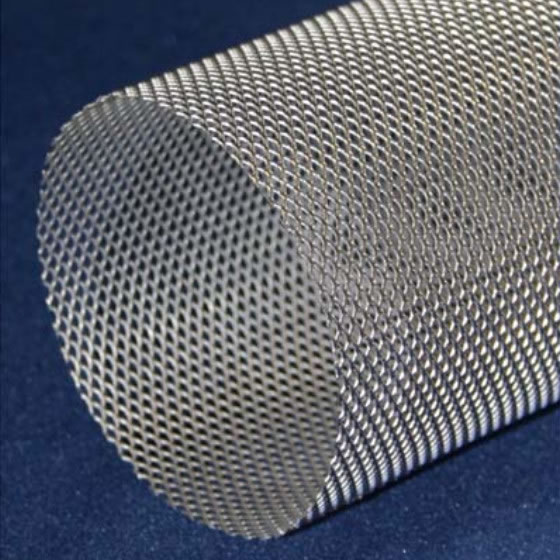

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services