Wire Form Manufacturers Serving Rhode Island

Use our thorough list of wire form manufacturers and suppliers in Rhode Island to examine and sort top wire form manufacturers with previews of ads and detailed descriptions of each product. Any wire form manufacturers can provide wire form products and services to meet your companies specific qualifications. An easy connection to reach wire form manufacturers through our fast request for quote form is provided as well. This source is right for you whether it's for rod bending, hardware, wire fabrication or any other wire form needs.

R & D Tool Engineering & Four-Slide Production, Inc.

Cranston, RI | 401-942-9710R & D Tool Engineering & Four-Slide Production, Inc. is a leading manufacturing company specializing in the production of Wire Forms. With a strong focus on precision engineering and innovative solutions, we have established ourselves as a trusted partner for a wide range of industries. Our commitment to excellence and customer satisfaction sets us apart in the market.

At R & D Tool...

Companies Serving Near Rhode Island

Acme Wire Products Company, Incorporated

Mystic, CT | 800-723-7015Acme Wire Products Company, Incorporated is a top precision wire fabricator located in Mystic Connecticut. We were started in the 1930’s by Rudolph Planeta and his brothers, their first products were wire lampshade frames. The brand continued to grow and in 1970 they began making products for the printer and computer industries. Today, we are run by a team of the Planeta siblings who work...

New England Spring

Bristol, CT | 860-589-3231At New England Spring, we pride ourselves on being a premier provider of high-quality wire forms and comprehensive solutions tailored to meet the diverse needs of our valued customers. With decades of experience and a steadfast commitment to excellence, we have established ourselves as a trusted leader in the wire forming industry.

Our product portfolio encompasses a wide range of wire ...

Plymouth Spring Company, Inc.

Bristol, CT | 860-584-0594Plymouth Spring Company, Inc. is a leading manufacturer and supplier of wire forms, offering a comprehensive range of products and service capabilities. With decades of experience in the industry, Plymouth Spring has established itself as a trusted partner for businesses across various sectors.

At Plymouth Spring, we specialize in the design, engineering, and production of high-quality ...

Cold Headed Parts

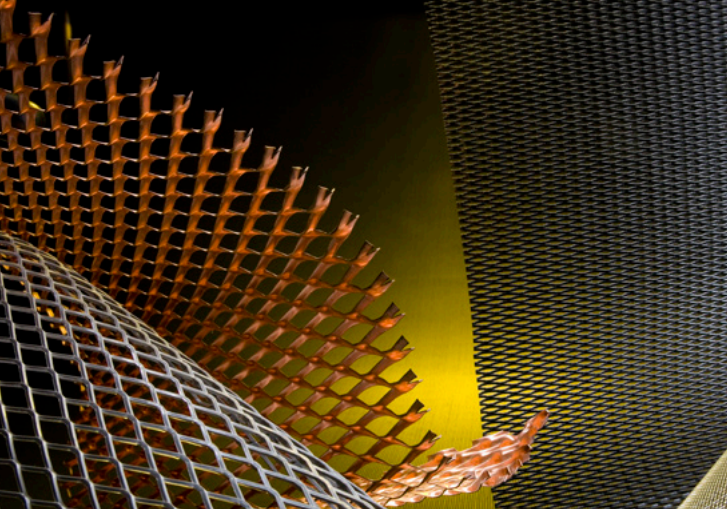

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

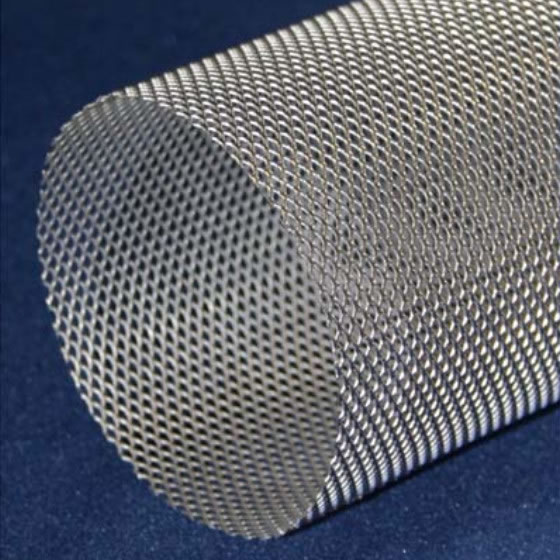

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

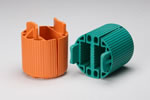

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services